In the realm of scientific research and development, high pressure lab reactors play a crucial role in enabling groundbreaking discoveries and advancements. These specialized devices provide researchers with the means to conduct experiments under controlled high-pressure conditions, simulating real-world scenarios and accelerating scientific progress. In this article, we will delve into the intricacies of high pressure lab reactors, exploring their applications, features, and their significance in various scientific disciplines. Additionally, we will present a compelling case study showcasing the transformative potential of these reactors in the field of catalysis.

I. Understanding High Pressure Lab Reactors

High pressure lab reactors are cutting-edge instruments designed to facilitate experiments that require elevated pressure conditions. These reactors are engineered to handle extreme pressures, allowing scientists to replicate and investigate phenomena that occur in natural environments such as deep-sea conditions, oil reservoirs, or the Earth’s crust. By subjecting substances to controlled high-pressure environments, researchers gain valuable insights into chemical reactions, material properties, and biological processes that occur under such conditions.

A. Definition and Purpose

A high pressure lab reactor, also known as a high-pressure autoclave or a pressurized vessel, is a robust apparatus used to create and sustain elevated pressure levels within a closed system. The primary purpose of these reactors is to enable scientists to conduct experiments under high-pressure conditions, which would otherwise be unattainable using conventional laboratory equipment. By replicating real-world scenarios, researchers can study the behavior of substances and materials under extreme pressure, allowing for a deeper understanding of their properties and reactions.

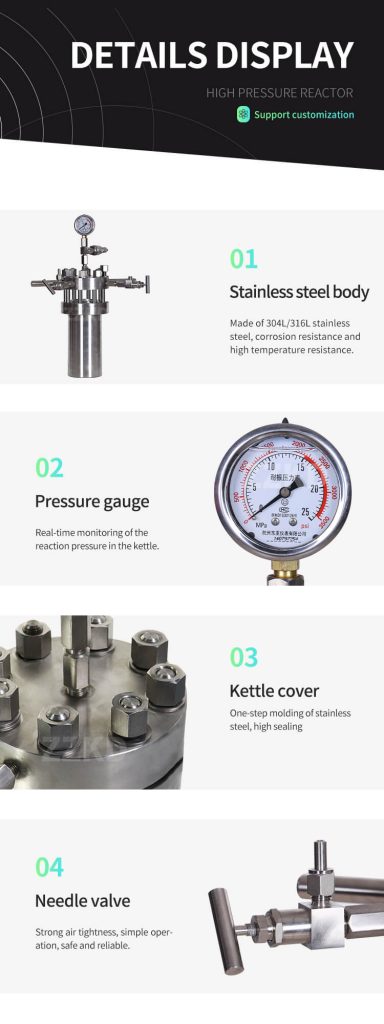

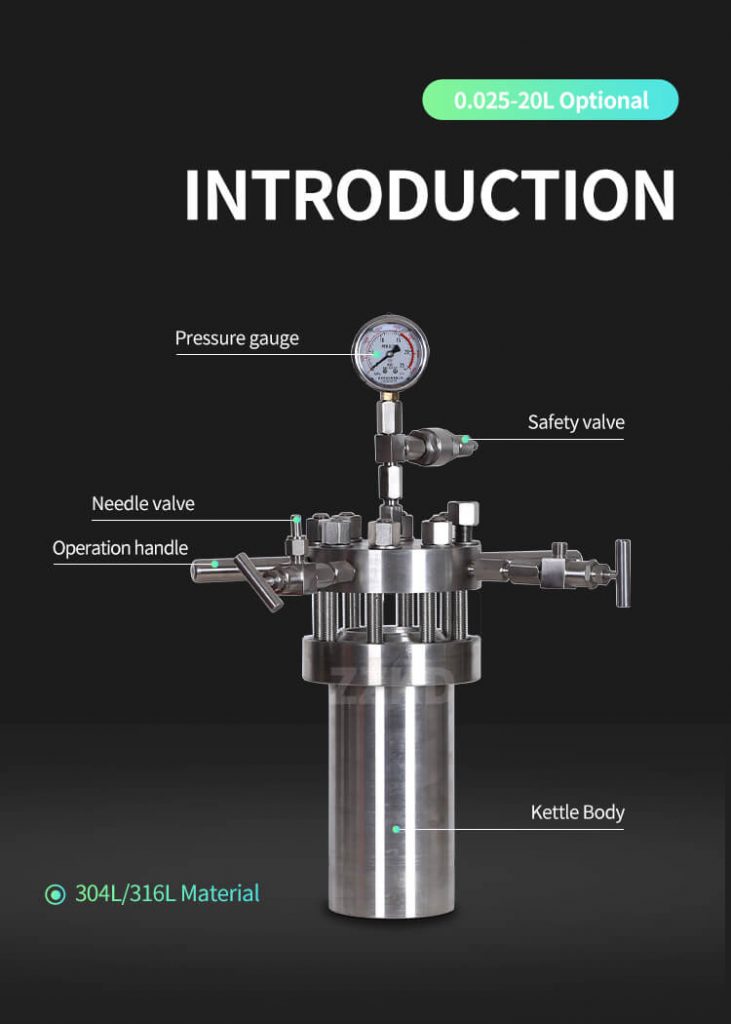

B. Key Components and Features

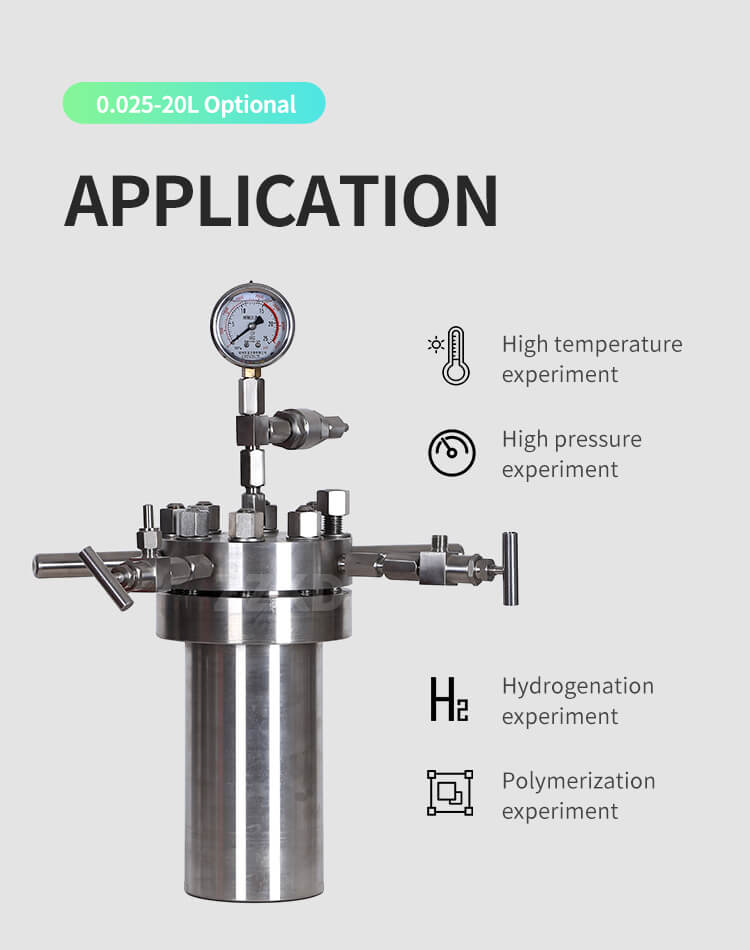

High pressure lab reactors consist of several essential components. The core structure is typically made of a durable material such as stainless steel or titanium, capable of withstanding high pressures without compromising the integrity of the system. The reactor is equipped with a pressure vessel, which contains the substances under investigation. To maintain the desired pressure, these reactors are equipped with a pressure control system, which includes pressure gauges, safety valves, and regulators. Furthermore, a heating or cooling system ensures precise temperature control within the reactor. Many modern high pressure lab reactors also incorporate advanced automation and control systems for enhanced accuracy and ease of operation.

C. Importance of High Pressure in Research

High pressure plays a crucial role in a wide range of scientific disciplines, including chemistry, physics, material science, and biology. Understanding the behavior of materials and substances under high pressure is vital for various applications, such as the synthesis of new chemical compounds, the development of advanced materials, and the investigation of biological processes. High pressure lab reactors enable researchers to study phase transitions, catalyst performance, chemical reactivity, and the effects of pressure on the physical and chemical properties of substances. These insights contribute to advancements in diverse fields, from energy storage and pharmaceuticals to environmental studies and food science.

II. Applications of High Pressure Lab Reactors

High pressure lab reactors find applications across numerous scientific domains, offering researchers a versatile tool to explore a wide range of phenomena under controlled high-pressure conditions.

A. Chemical Synthesis and Catalysis

In chemical synthesis, high pressure lab reactors are invaluable for developing novel compounds with enhanced properties. By subjecting reactants to high pressures, researchers can accelerate reaction rates, increase yields, and explore unique reaction pathways. High pressure catalysis, in particular, benefits from the ability to tune reaction conditions and optimize catalyst performance. These reactors enable the investigation of complex catalytic processes, paving the way for more efficient and sustainable chemical transformations.

B. Material Science and Nanotechnology

In the field of material science, high pressure lab reactors provide researchers with a means to explore the synthesis and characterization of advanced materials. The application of high pressure can induce structural transformations, modify material properties, and generate novel phases. These reactors are instrumental in studying high-pressure polymorphism, superconductivity, and phase transitions, offering insights into the design and development of new materials with tailored properties. Additionally, in nanotechnology, high pressure reactors aid in the synthesis and assembly of nanoscale structures, enabling the fabrication of functional materials with enhanced performance.

C. Pharmaceutical and Biomedical Research

High pressure lab reactors have a significant impact on pharmaceutical and biomedical research. They enable the study of drug stability, formulation, and synthesis under high-pressure conditions, leading to the development of more effective and stable pharmaceutical products. In biomedical research, these reactors simulate physiological conditions, allowing researchers to investigate drug delivery systems, biomaterials, and the effects of high pressure on biological tissues. Such investigations provide valuable insights for drug development, tissue engineering, and medical device design.

D. Food Science and Quality Control

The application of high pressure in the food industry has gained momentum in recent years. High pressure lab reactors facilitate the study of food processing techniques, such as high-pressure pasteurization and sterilization, which can extend the shelf life of products while preserving nutritional value. Additionally, these reactors enable researchers to explore the effects of high pressure on food quality, texture, and flavor, leading to the development of innovative food processing methods and improved food safety practices.

E. Environmental Studies and Renewable Energy

Understanding the impact of high pressure on natural processes is crucial for environmental studies and renewable energy research. High pressure lab reactors aid in the investigation of geological phenomena, such as deep-sea ecosystems, hydrocarbon reservoirs, and carbon capture and storage techniques. By simulating high-pressure conditions, scientists can analyze the behavior of materials and substances under extreme environments, contributing to the development of sustainable energy technologies and environmental preservation strategies.

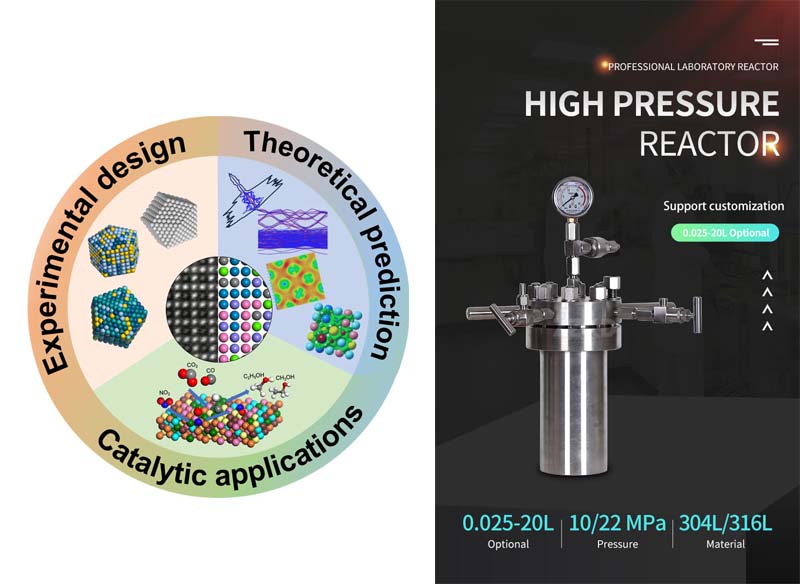

III. Case: Catalysis Research Advancements

To showcase the transformative potential of high pressure lab reactors, let us explore a case study highlighting their impact on catalysis research.

A. Background and Motivation

Catalysis plays a vital role in various industrial processes, from petrochemical production to environmental remediation. Researchers sought to enhance the efficiency and selectivity of catalysts for specific reactions. By leveraging the capabilities of high pressure lab reactors, scientists aimed to explore the influence of pressure on catalytic reactions, as well as the structural changes occurring in catalyst materials under high-pressure conditions.

B. Experimental Setup and Methodology

In the case study, researchers employed a high pressure lab reactor capable of reaching pressures up to 1000 bar. They selected a catalytic system and subjected it to a range of pressures while monitoring the reaction progress. The reactor’s advanced control system allowed precise regulation of pressure and temperature throughout the experiment. In-situ characterization techniques, such as spectroscopy and microscopy, provided real-time insights into catalyst behavior and structural changes.

C. Results and Findings

The study revealed that high pressure significantly influenced the catalytic activity and selectivity of the tested system. At specific pressure ranges, researchers observed improved reaction rates and enhanced product yields. Moreover, they discovered that high pressure induced structural changes in the catalyst, leading to modifications in active sites and reaction pathways. These findings provided valuable knowledge for optimizing catalyst design and reaction conditions, potentially leading to more sustainable and efficient industrial processes.

D. Significance and Future Implications

The case study demonstrated the critical role of high pressure lab reactors in catalysis research. By enabling investigations under high-pressure conditions, scientists gained a deeper understanding of the complex interplay between pressure, catalyst structure, and reaction kinetics. The obtained insights open new avenues for designing tailored catalysts and optimizing catalytic processes for a broad range of applications, including energy production, chemical manufacturing, and environmental remediation.

IV. High Pressure Lab Reactors Advantages and Challenges

While high pressure lab reactors offer significant advantages, certain challenges must be considered when conducting experiments under elevated pressure conditions.

A. Advantages of High Pressure Lab Reactors

1. Replication of Real-World Conditions: High pressure lab reactor allow researchers to mimic and study processes that occur in extreme environments, providing valuable data for a wide range of applications.

2. Enhanced Reaction Rates and Selectivity: High pressure can accelerate reactions and favor specific reaction pathways, leading to increased yields and improved selectivity.

3. Tailored Material Properties: High pressure facilitates the synthesis and modification of materials with unique properties, expanding the possibilities for technological advancements.

4. Insight into Biological Processes: High pressure lab reactors enable the investigation of biological systems under conditions simulating deep-sea environments or physiological pressures, aiding biomedical research and drug development.

B. Challenges in High Pressure Experimentation

1. Safety Considerations: High-pressure experiments require strict safety protocols to prevent accidents and ensure operator well-being. Proper training, reliable pressure vessels, and safety features are crucial.

2. Equipment Complexity: High pressure lab reactors often involve intricate designs and require specialized knowledge for operation, maintenance, and data interpretation.

3. High Costs: Acquiring and maintaining high pressure lab reactor can be expensive, limiting accessibility for some research institutions and hindering widespread adoption.

V. High Pressure Lab Reactors Safety Considerations and Regulations

Operating high pressure lab reactor demands strict adherence to safety protocols and compliance with regulatory guidelines.

A. Ensuring Operator Safety

1. Adequate Training: Comprehensive training is necessary for personnel in high-pressure experiments, covering safe equipment operation, emergency procedures, and risk assessment.

2. Equipment Inspection and Maintenance: Ensure pressure vessel, safety valve, and critical component integrity by performing regular inspections and maintenance checks.

3. Proper Venting and Pressure Release: Equipping high pressure lab reactors with reliable pressure relief systems prevents over-pressurization and enables controlled venting during emergencies.

B. Regulatory Guidelines for High Pressure Lab Reactors

1. Compliance with Standards: Adherence to safety standards and regulations for high pressure equipment and substances is essential for researchers.

2. Risk Assessment and Management: Comprehensive risk assessments should be conducted to identify potential hazards associated with high pressure experiments. Mitigation measures must be implemented accordingly.

VI. Emerging Trends and Technological Innovations

Continuous advancements in high pressure lab reactors shape scientific research and open new avenues for exploration.

A. Integration of Automation and Control Systems

High pressure lab reactors now feature sophisticated automation and control systems for precise regulation of experimental parameters. This integration enhances accuracy, reproducibility, and data acquisition, making experiments more efficient and reliable.

B. Miniaturized High Pressure Lab Reactors

Researchers are developing miniaturized high pressure lab reactors, also known as microreactors or lab-on-a-chip systems. These compact devices offer advantages such as reduced sample volume requirements, faster heat transfer, and improved control over reaction parameters. Miniaturized reactors have the potential to revolutionize high pressure experimentation, enabling high-throughput screening and enhancing process optimization.

C. In-situ Monitoring and Characterization Techniques

Advanced in-situ monitoring and characterization in high pressure lab reactors enable real-time observation and analysis of reactions. Spectroscopy, microscopy, and other tools yield insights into catalyst behavior, material transformations, and reaction kinetics, deepening high-pressure process understanding.

In summary, high pressure lab reactors have emerged as indispensable tools for researchers across various scientific domains. Creating and sustaining high-pressure environments allows studying complex chemical reactions, material transformations, and inaccessible biological processes. From catalysis to nanotechnology, pharmaceutical research to environmental studies, these reactors open doors to new possibilities and breakthroughs. Staying updated on advancements and safety measures is crucial to unlock high pressure lab reactors’ full potential. Continuing technological evolution will bring revolutionary innovations, reshaping our understanding and transforming scientific research.