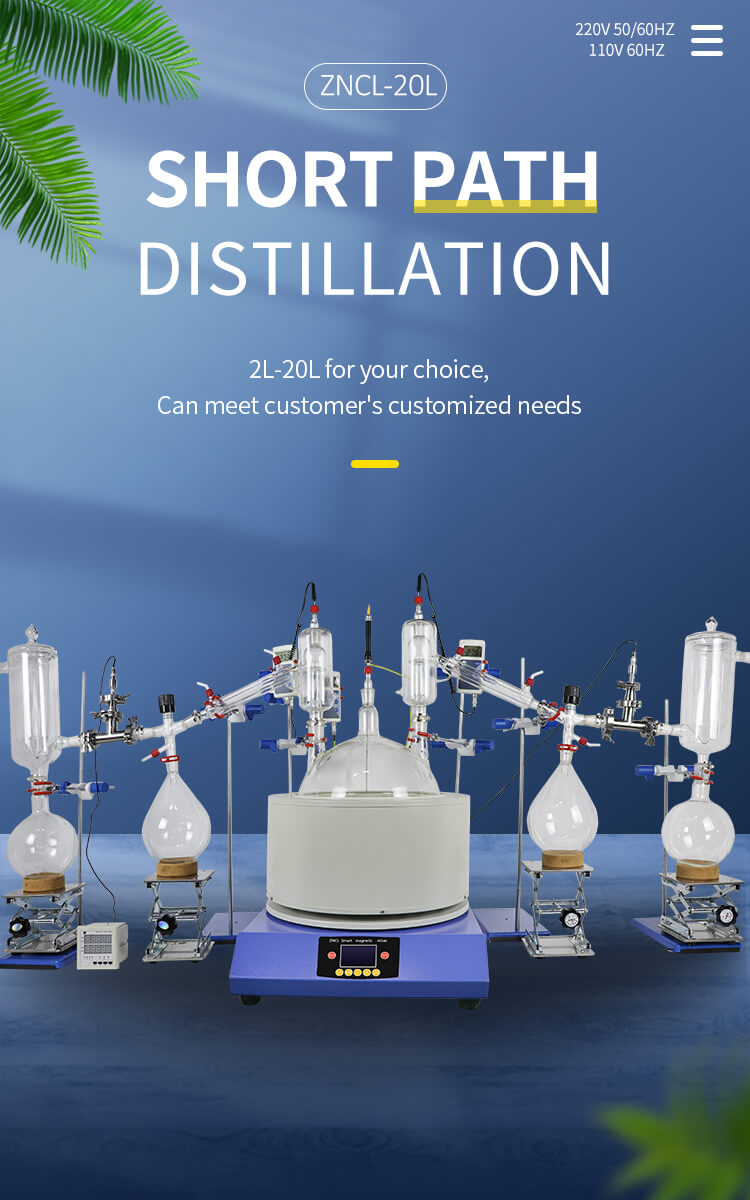

Short path distillation unit introduction

Short path distillation is a process used to purify and separate mixtures of liquids with different boiling points. It is particularly effective for separating compounds with similar boiling points or thermal stability, and is widely used in the fields of chemistry, pharmaceuticals, and food processing.

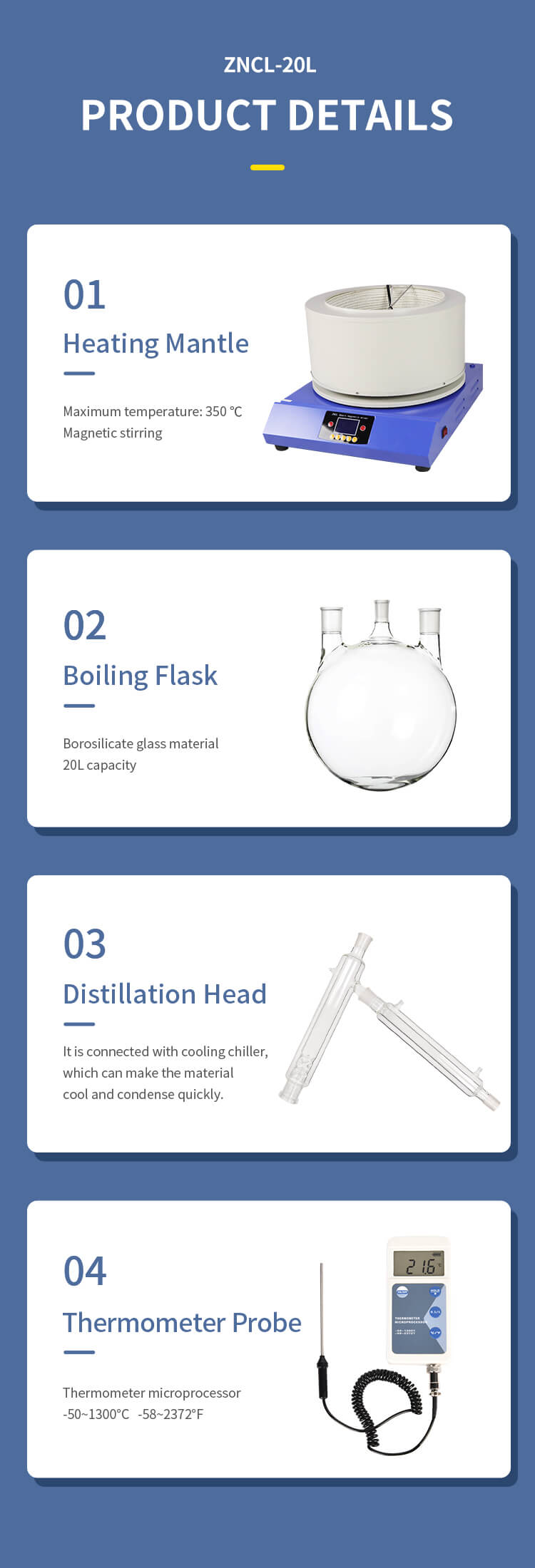

A short path distillation unit typically consists of a heating mantle or bath, a distillation flask or vessel, a condenser, a vacuum pump, and a receiving flask. The mixture to be separated is heated and vaporized in the distillation flask, and the vapor is then condensed and collected in the receiving flask. The condenser is designed to minimize the distance the vapor travels from the distillation flask to the receiving flask, hence the name “short path” distillation.

The vacuum pump is used to reduce the pressure in the system, which lowers the boiling point of the mixture and allows for distillation to occur at lower temperatures. This is particularly useful for heat-sensitive compounds that would decompose or react at higher temperatures.

Short path distillation is an efficient and effective method for separating and purifying complex mixtures of liquids. It is often used in the production of high-purity compounds for use in research, development, and industrial applications.

Short path distillation unit Features:

Short path distillation units have a number of features that make them particularly useful for separating and purifying complex mixtures of liquids. Some key features include:

High Separation Efficiency: Short path distillation units are designed to maximize the efficiency of separation by minimizing the distance that the vapor travels from the distillation flask to the receiving flask. This allows for more precise separation of compounds with similar boiling points or thermal stabilities.

Low Operating Temperature: The vacuum pump used in short path distillation reduces the pressure in the system, which in turn lowers the boiling point of the mixture. This allows for distillation to occur at lower temperatures, which is particularly useful for heat-sensitive compounds that would decompose or react at higher temperatures.

Versatility: Short path distillation units can be used to separate and purify a wide range of compounds, including oils, waxes, and other organic materials.

High Purity: Short path distillation units are able to produce high-purity compounds, with purities ranging from 90% to 99.9% or higher, depending on the application.

Scalability: Short path distillation units can be scaled up or down depending on the amount of material being processed, making them suitable for both small-scale laboratory research and large-scale industrial production.

Easy to Clean and Maintain: Short path distillation units are typically made from high-quality materials such as borosilicate glass and stainless steel, which are easy to clean and maintain.

short path distillation units are a versatile and efficient tool for separating and purifying complex mixtures of liquids, making them an essential part of many laboratory and industrial processes.

Short path distillation unit Application:

Short path distillation units have a wide range of applications in many different industries, including:

Cannabis and Hemp Processing: Short path distillation is commonly used in the production of cannabis and hemp extracts, such as THC or CBD oil. It allows for the separation and purification of these compounds from other plant materials and contaminants, resulting in high-purity extracts suitable for use in a variety of products.

Essential Oils: Short path distillation is used to extract and purify essential oils from plant materials, such as lavender or eucalyptus. This allows for the production of high-quality, concentrated oils that are used in perfumes, cosmetics, and aromatherapy products.

Food and Beverage Processing: Short path distillation is used in the production of food and beverage products, such as alcoholic beverages and flavorings. It allows for the separation and purification of volatile compounds, resulting in products with consistent flavor and aroma profiles.

Pharmaceuticals: Short path distillation is used in the production of pharmaceuticals, such as antibiotics and other active ingredients. It allows for the separation and purification of compounds with high levels of purity, which is essential for ensuring the safety and efficacy of pharmaceutical products.

Chemical Manufacturing: Short path distillation is used in the production of a wide range of chemicals, including solvents, polymers, and specialty chemicals. It allows for the separation and purification of complex mixtures, resulting in high-purity products with consistent quality.

Short path distillation is a versatile tool that is used in a wide range of industries for the separation and purification of complex mixtures of liquids.

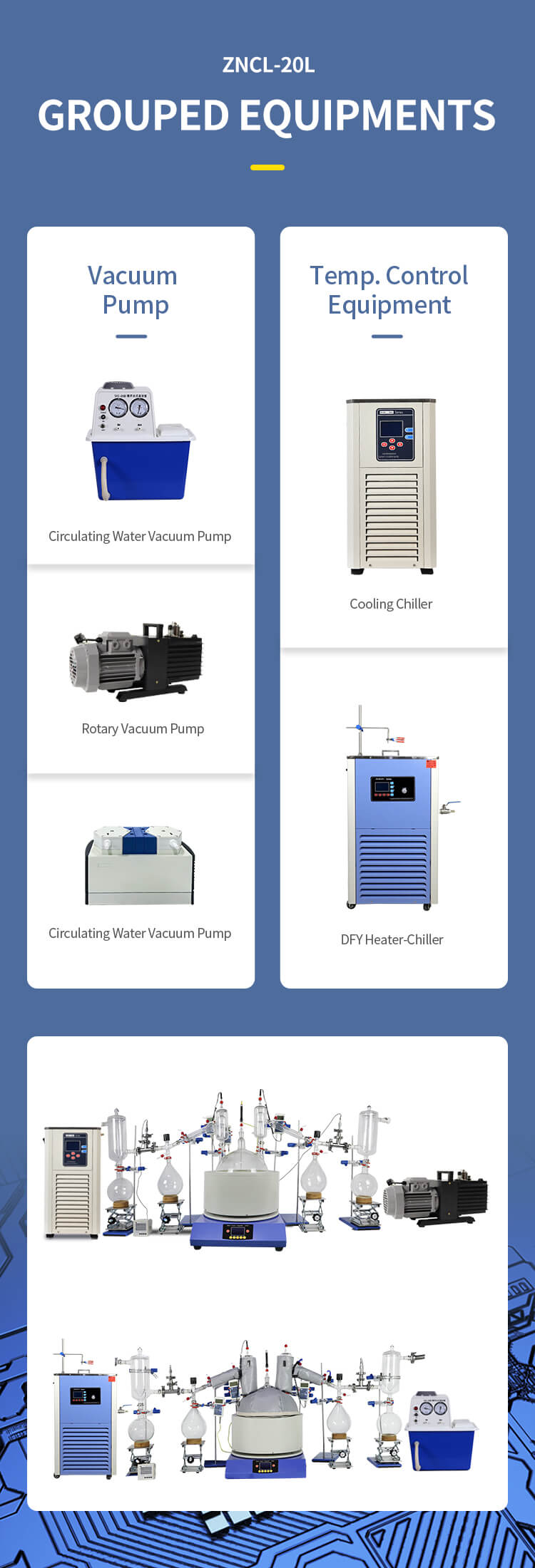

Supporting Equipment for Short path distillation unit:

DLSB-30/30 Refrigerated Circulator

Storage Volume: 30L

Low temperature range: -30℃~RT

Refrigeration capacity: 363~2722W

Rated Power: 1950W

SHZ-C Water Circulating Vacuum Pump

Power: 370W

Flow(L/min): 80

Lift(m): 12

Max.Vacuum(Mpa): 0.098

Tank Capacity: 50L

2XZ-4 Rotary Vane Vacuum Pump

Power: 550w

Exhaust speed (L/S):4

Rotating speed:1400

Air inlet diameter:Φ19

Noise (db):≤60

Case : ZZKD Company Selling Short path distillation unit to a Malaysian Customer

ZZKD company, a leading manufacturer of short path distillation units, recently sold a 20L short path distillation unit to a customer in Malaysia. The customer, a chemical manufacturing company, was in need of a reliable and efficient tool for the separation and purification of complex mixtures of liquids.

The customer had a number of requirements for the short path distillation unit, including high separation efficiency, low operating temperature, and scalability. After researching various suppliers, the customer chose ZZKD company due to their reputation for high-quality products and excellent customer service.

The 20L short path distillation unit provided by ZZKD company was able to meet all of the customer’s requirements. It was designed to maximize the efficiency of separation by minimizing the distance that the vapor traveled from the distillation flask to the receiving flask, allowing for more precise separation of compounds with similar boiling points or thermal stabilities. The vacuum pump used in the unit reduced the pressure in the system, which allowed for distillation to occur at lower temperatures, making it suitable for heat-sensitive compounds.

The short path distillation unit was also scalable, allowing the customer to process different amounts of material depending on their needs. It was easy to clean and maintain, with high-quality materials such as borosilicate glass and stainless steel used in its construction.

After using the 20L short path distillation unit provided by ZZKD company, the customer was highly satisfied with its performance. They reported that the unit was able to effectively separate and purify their complex mixtures of liquids, resulting in high-purity products with consistent quality. The customer also praised ZZKD company for their excellent customer service, noting that they were responsive and helpful throughout the entire sales process.

Overall, the sale of the 20L short path distillation unit to the Malaysian customer was a success for ZZKD company. The customer was able to meet their needs for the separation and purification of complex mixtures of liquids, and ZZKD company was able to provide a high-quality product and excellent customer service. This case highlights the versatility and effectiveness of short path distillation units, as well as the importance of choosing a reliable supplier for such equipment.