5L short path distillation kit introduction

A short path distillation kit is a specialized distillation apparatus used to purify and separate complex mixtures of compounds with high boiling points. It is commonly used in the chemical, pharmaceutical, and cannabis industries for refining oils and extracting active ingredients.

A 5L short path distillation kit typically includes a boiling flask, a condenser, a receiving flask, a heating mantle or oil bath, a vacuum pump, and a cold trap. The kit is designed to operate under high vacuum conditions, which allows for low temperature distillation of compounds with high boiling points.

To use the kit, the mixture to be distilled is first placed in the boiling flask and heated. The vapors produced by the heating process rise up into the condenser, which cools and condenses them back into a liquid form. The resulting liquid is then collected in the receiving flask.

The cold trap is used to prevent any vapors from escaping into the vacuum pump, which can damage the pump and contaminate the distillate. The vacuum pump is used to maintain a low pressure in the system, which allows for efficient distillation at lower temperatures.

5L short path distillation kit is a powerful tool for refining and purifying complex mixtures of compounds. However, it requires specialized training and knowledge to operate safely and effectively, and should only be used by trained professionals with proper safety equipment and procedures in place.

5L short path distillation kit Features:

A 5L short path distillation kit typically offers several features that make it an efficient and effective tool for separating and purifying complex mixtures of compounds. Some of the key features of a 5L short path distillation kit include:

High-quality glassware: The kit typically includes high-quality borosilicate glassware, which is resistant to high temperatures and chemical corrosion, making it ideal for distillation applications.

Precise temperature control: The kit typically includes a heating mantle or oil bath that provides precise temperature control, allowing for low-temperature distillation of heat-sensitive compounds.

Efficient cooling: The kit typically includes a high-quality condenser that provides efficient cooling of the distillate vapors, allowing for efficient separation and purification of compounds.

Vacuum control: The kit typically includes a vacuum pump and a cold trap, which work together to maintain a low pressure in the system, allowing for efficient distillation at lower temperatures.

Ease of use: The kit is designed to be easy to use and maintain, with simple assembly and disassembly of the glassware, and easy access to all components for cleaning and maintenance.

Safe operation: The kit typically includes safety features such as over-temperature protection, over-current protection, and pressure relief valves, which ensure safe and reliable operation of the distillation process.

5L short path distillation kit offers a range of features that make it a powerful tool for separating and purifying complex mixtures of compounds, while also ensuring safe and efficient operation.

5L short path distillation kit Application:

A 5L short path distillation kit has a wide range of applications in various industries, including:

Chemical industry: The kit can be used for the separation and purification of complex chemical mixtures, such as polymers, resins, and other high-boiling-point compounds.

Pharmaceutical industry: The kit can be used for the isolation and purification of active pharmaceutical ingredients (APIs) from natural sources or chemical synthesis.

Cannabis industry: The kit can be used for the extraction and purification of cannabinoids and terpenes from cannabis plants, which are used for medicinal and recreational purposes.

Essential oil industry: The kit can be used for the extraction and purification of essential oils from plants, such as lavender, peppermint, and eucalyptus.

Food and beverage industry: The kit can be used for the purification of food-grade compounds, such as flavors and fragrances, and for the removal of impurities from alcoholic beverages.

5L short path distillation kit offers a versatile tool for separating and purifying complex mixtures of compounds, making it a valuable asset for a wide range of industries.

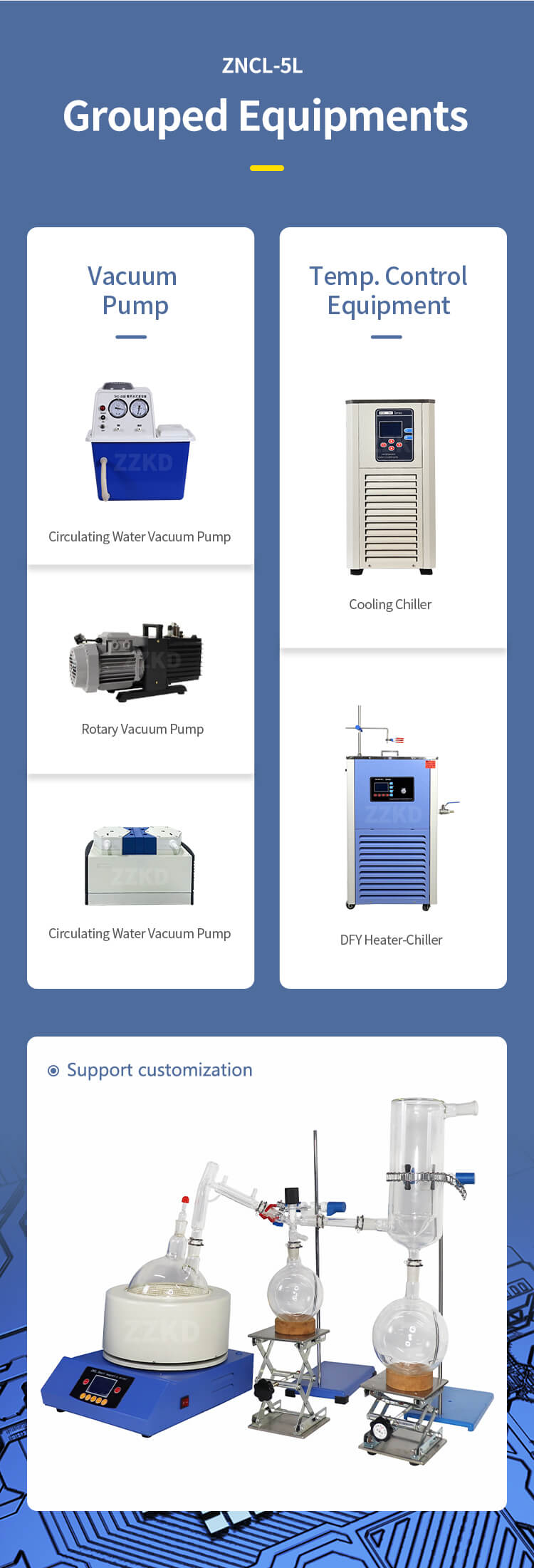

Supporting Equipment for 5L short path distillation kit:

DLSB-5/10 Refrigerated Circulator

Storage Volume: 5L

Low temperature range: -10℃~RT

Refrigeration capacity: 280~620W

Rated Power: 420W

SHZ-D(Ⅲ) Water Circulating Vacuum Pump

Power: 180W

Flow(L/min): 60

Lift(m): 8

Max.Vacuum(Mpa): 0.098

Tank Capacity: 15L

2XZ-1 Rotary Vane Vacuum Pump

Power: 250w

Exhaust speed (L/S):1

Rotating speed:1400

Air inlet diameter:Φ13

Noise (db):≤60

Case : ZZKD Company Selling 5L short path distillation kit to an American Customer

ZZKD is a leading manufacturer of scientific instruments based in China, providing a wide range of high-quality laboratory equipment for industries such as chemical, pharmaceutical, and cannabis. Recently, ZZKD received an order for a 5L short path distillation kit from an American customer.

The customer, a cannabis extraction company based in California, needed a reliable and efficient distillation kit for their production process. They had previously used a different brand of distillation equipment but were not satisfied with its performance and durability.

After researching and comparing various brands, the customer chose ZZKD’s 5L short path distillation kit for its high-quality glassware, precise temperature control, and efficient cooling system. They also appreciated the kit’s ease of use and maintenance, as well as ZZKD’s reputation for providing excellent customer service and technical support.

Upon receiving the distillation kit, the customer was impressed with its sturdy and well-designed glassware and the kit’s overall build quality. They found the kit easy to assemble and disassemble, and the heating and cooling system provided precise and consistent temperature control. The vacuum pump and cold trap also worked well, maintaining a low pressure in the system for efficient distillation.

The customer was able to use the distillation kit to extract and purify cannabinoids from cannabis plants, producing a high-quality distillate with minimal impurities. They noted that the distillation process was much faster and more efficient than their previous equipment, and they were able to increase their production output while maintaining high quality.

The customer was also pleased with ZZKD’s customer service and technical support, noting that their questions and concerns were addressed promptly and professionally. They felt confident in their purchase and would recommend ZZKD’s 5L short path distillation kit to other companies in the cannabis industry.

In summary, ZZKD’s 5L short path distillation kit proved to be a reliable and efficient solution for the customer’s extraction needs. Its high-quality glassware, precise temperature control, and efficient vacuum system helped the customer achieve high-quality distillate with minimal impurities, increasing their production output and maintaining high quality. The customer’s positive feedback and recommendation are a testament to ZZKD’s commitment to providing excellent laboratory equipment and customer service.