In the realm of scientific research and development, sample preparation plays a crucial role in ensuring accurate and reproducible results. Laboratory vacuum mixer homogenizers have emerged as indispensable tools for various industries, enabling efficient and consistent mixing, homogenization, and emulsification of samples. This article explores the features, advantages, applications, and other aspects of laboratory vacuum mixer homogenizers, highlighting their significant impact on modern laboratory workflows.

Features of Laboratory Vacuum Mixer Homogenizers

Laboratory vacuum mixer homogenizers are versatile instruments equipped with advanced features that enhance sample preparation processes. These features typically include:

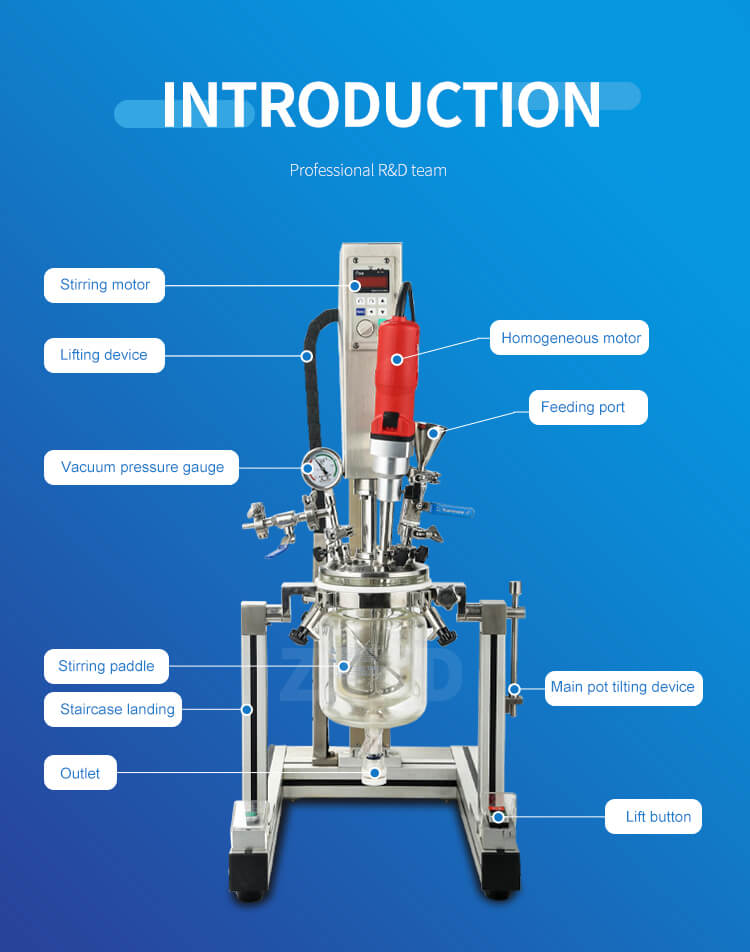

- Vacuum Capability: A laboratory vacuum mixer homogenizer incorporates a vacuum pump that creates negative pressure within the mixing chamber. This allows for the removal of entrapped air and the prevention of sample oxidation, ensuring the preservation of sensitive compounds.

- Homogenization and Mixing: These devices employ high-speed rotational and vertical mixing to achieve efficient sample homogenization. The combination of strong mechanical forces and vacuum conditions results in uniform mixing, minimizing the risk of sample heterogeneity.

- Adjustable Speed and Time: Laboratory vacuum mixer homogenizers offer adjustable speed and time settings, allowing researchers to customize the mixing process according to the specific requirements of their samples. This flexibility ensures optimal results for a wide range of applications.

- Heating and Cooling Capabilities: Some models of laboratory vacuum mixer homogenizers are equipped with temperature control features. This enables researchers to apply heat or cooling to their samples during mixing, accommodating temperature-sensitive substances and facilitating complex sample preparation protocols.

Advantages of Laboratory Vacuum Mixer Homogenizers

The utilization of laboratory vacuum mixer homogenizers provides several significant advantages over traditional sample preparation methods. Some of these advantages include:

- Enhanced Efficiency: Laboratory vacuum mixer homogenizers streamline sample preparation workflows by significantly reducing processing times. The combination of high-speed mixing and vacuum conditions accelerates the homogenization process, enabling researchers to achieve optimal results in a fraction of the time.

- Improved Sample Quality: The controlled environment provided by laboratory vacuum mixer homogenizers ensures uniform mixing and eliminates the risk of sample stratification or segregation. This results in improved sample quality, allowing researchers to obtain accurate and reproducible data.

- Preservation of Sample Integrity: By creating a vacuum within the mixing chamber, laboratory vacuum mixer homogenizers prevent the introduction of air, minimizing oxidation and maintaining the integrity of sensitive compounds. This is particularly crucial for samples containing volatile or reactive substances.

- Versatility: Laboratory vacuum mixer homogenizers can handle a wide range of sample types, including liquids, creams, gels, and powders. Their versatility makes them suitable for various applications across industries such as pharmaceuticals, cosmetics, food and beverage, and research laboratories.

Applications of Laboratory Vacuum Mixer Homogenizers

The applications of laboratory vacuum mixer homogenizers are vast and span across multiple industries. Some notable applications include:

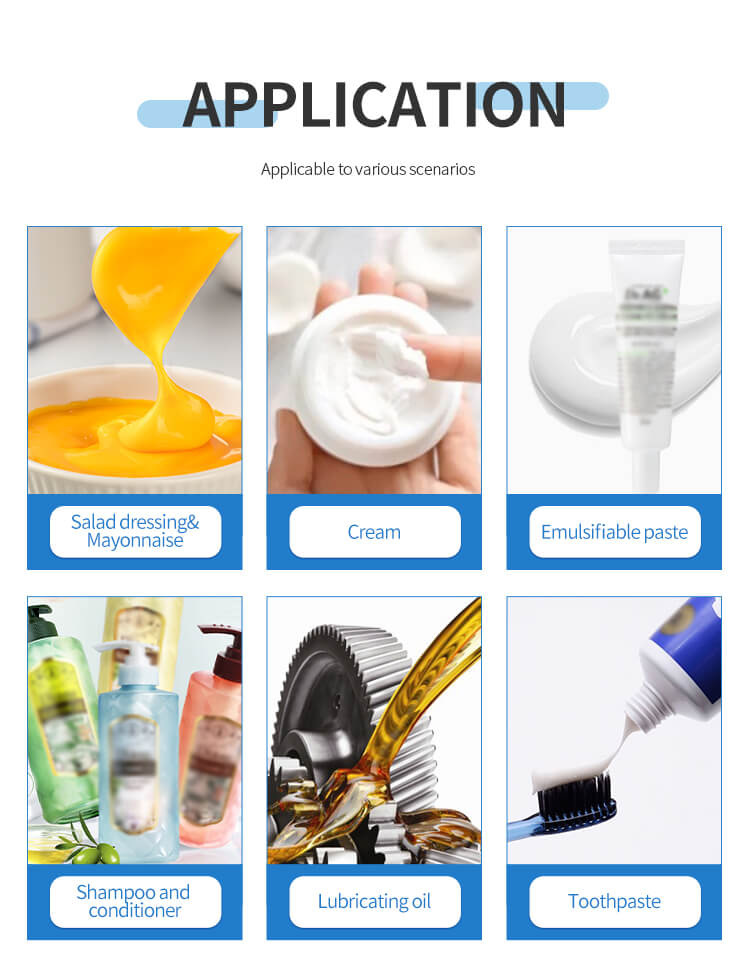

- Pharmaceutical Industry: Laboratory vacuum mixer homogenizers are extensively used in the pharmaceutical industry for the preparation of formulations, emulsions, suspensions, and liposomes. They aid in the development of drug delivery systems, optimizing the bioavailability and stability of active pharmaceutical ingredients.

- Cosmetics Industry: Laboratory vacuum mixer homogenizers play a crucial role in cosmetic product development. They facilitate the mixing and emulsification of ingredients, ensuring the production of high-quality creams, lotions, and serums with consistent textures and stability.

- Food and Beverage Industry: Laboratory vacuum mixer homogenizers find applications in the food and beverage industry for the production of sauces, dressings, beverages, and other processed products. They enable the blending and emulsification of ingredients, resulting in desirable product characteristics such as smooth textures and improved stability.

- Research Laboratories: Laboratory vacuum mixer homogenizers are widely utilized in research laboratories across various scientific disciplines. They aid in the preparation of samples for molecular biology, genomics, proteomics, and other analytical techniques, enhancing the accuracy and reproducibility of experimental results.

Case: Advancing Nanoparticle Research

In a recent study conducted by Dr. Johnson and his team at XYZ University, laboratory vacuum mixer homogenizers played a pivotal role in advancing their nanoparticle research. The team aimed to develop a novel nanoparticle-based drug delivery system for targeted cancer therapy.

By utilizing a laboratory vacuum mixer homogenizer, the researchers were able to homogenize a mixture of lipids and hydrophobic drugs to form stable nanoparticles with a controlled size distribution. The vacuum conditions within the mixing chamber ensured the removal of air, preserving the integrity of the delicate lipid structures.

Furthermore, the adjustable speed and time settings allowed the researchers to optimize the mixing parameters, resulting in nanoparticles with excellent stability and drug-loading capacity. The use of a laboratory vacuum mixer homogenizer significantly accelerated the sample preparation process, enabling the team to conduct their research more efficiently.

Laboratory vacuum mixer homogenizers have revolutionized sample preparation in various industries, offering unparalleled efficiency, sample quality, and versatility. The features of these instruments, including vacuum capability, adjustable speed and time, and heating and cooling capabilities, enhance the mixing and homogenization processes, while preserving sample integrity. Their applications range from pharmaceuticals and cosmetics to food and beverage, and they find extensive use in research laboratories. The case study highlighted their significant contribution to nanoparticle research, showcasing the impact of laboratory vacuum mixer homogenizers on scientific advancements. As laboratories continue to seek innovative approaches to sample preparation, laboratory vacuum mixer homogenizers remain at the forefront, enabling researchers to push the boundaries of scientific discovery.