In the realm of chemical and pharmaceutical equipment, the Agitated Nutsche Filter Dryer (ANFD) stands as a technological marvel. Its multifaceted capabilities and applications have earned it a prominent place in industries worldwide. In this article, we will delve into the intricacies of the Agitated Nutsche Filter Dryer, exploring its design, functionality, applications, advantages, and the pivotal role it plays in modern manufacturing processes.

1. Understanding the Agitated Nutsche Filter Dryer

The Agitated Nutsche Filter Dryer, often abbreviated as Agitated Nutsche Filter Dryer, is a sophisticated piece of equipment that combines multiple functions into a single vessel. It is essentially a filtration device that also incorporates features of agitation, drying, and discharge. This ingenious integration makes it an indispensable tool for various industries, particularly in the chemical and pharmaceutical sectors.

A. The Key Components

The Agitated Nutsche Filter Dryer comprises several vital components, including a filter plate, agitator, jacket for heating or cooling, and a discharge system. These components work harmoniously to facilitate the filtration and drying of solid-liquid mixtures efficiently.

B. Working Principles

The Agitated Nutsche Filter Dryer operates on a simple yet effective principle. It begins by suspending the solid-liquid mixture in a slurry form. Subsequently, the filter plate separates the solid particles from the liquid, allowing the filtrate to pass through. Meanwhile, the agitator ensures proper mixing and drying of the solids, aided by the heating or cooling jacket as required. Finally, the discharge system expels the dried product, leaving you with high-quality solids and a clarified liquid.

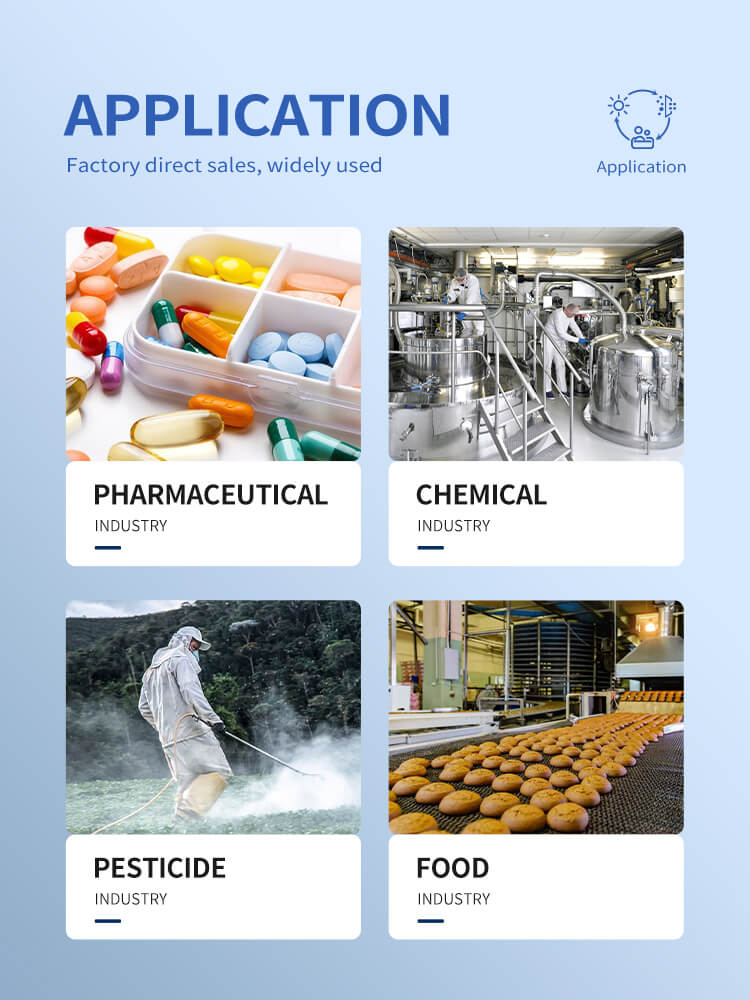

2. Applications Across Industries

The versatility of the Agitated Nutsche Filter Dryer extends its applications to a wide range of industries, including pharmaceuticals, chemicals, food, and more. Let’s explore some key sectors where Agitated Nutsche Filter Dryers play a pivotal role.

A. Pharmaceutical Industry

In the pharmaceutical sector, precision and purity are paramount. Agitated Nutsche Filter Dryers are used extensively for isolating and drying active pharmaceutical ingredients (APIs). Their ability to handle sensitive compounds and maintain sterility makes them invaluable in drug manufacturing.

B. Chemical Manufacturing

Chemical processes often involve the separation and drying of solid compounds. Agitated Nutsche Filter Dryers are employed to achieve these tasks efficiently, ensuring high-quality products and minimizing wastage.

C. Food Processing

In food processing, maintaining product quality and safety is essential. Agitated Nutsche Filter Dryers are utilized to separate liquids from solids in processes like vegetable oil refining, ensuring the removal of impurities and contaminants.

3. Advantages of Agitated Nutsche Filter Dryers

The Agitated Nutsche Filter Dryer offers several advantages that contribute to its widespread adoption in various industries.

A. Efficient and Time-saving

One of the primary advantages of Agitated Nutsche Filter Dryers is their efficiency. They can perform multiple operations – filtration, washing, drying, and discharge – in a single vessel, significantly reducing processing time and labor costs.

B. Product Quality Assurance

Agitated Nutsche Filter Dryers enable precise control over the drying process, minimizing the risk of product contamination and ensuring consistent product quality.

C. Flexibility and Customization

Manufacturers can customize Agitated Nutsche Filter Dryers to meet specific process requirements. This adaptability makes them suitable for a wide range of applications.

4. Maintenance and Longevity

To maximize the lifespan and efficiency of Agitated Nutsche Filter Dryers, proper maintenance is crucial. Regular cleaning, inspection, and routine servicing ensure that these machines continue to perform at their best.

5. Conclusion

In conclusion, the Agitated Nutsche Filter Dryer is a versatile and indispensable piece of equipment in the chemical and pharmaceutical industries. Its ability to combine filtration, agitation, drying, and discharge functions into a single vessel streamlines processes, enhances product quality, and saves both time and resources. As technology continues to advance, Agitated Nutsche Filter Dryers are poised to play an even more significant role in manufacturing processes, reaffirming their status as a cornerstone of modern industry.

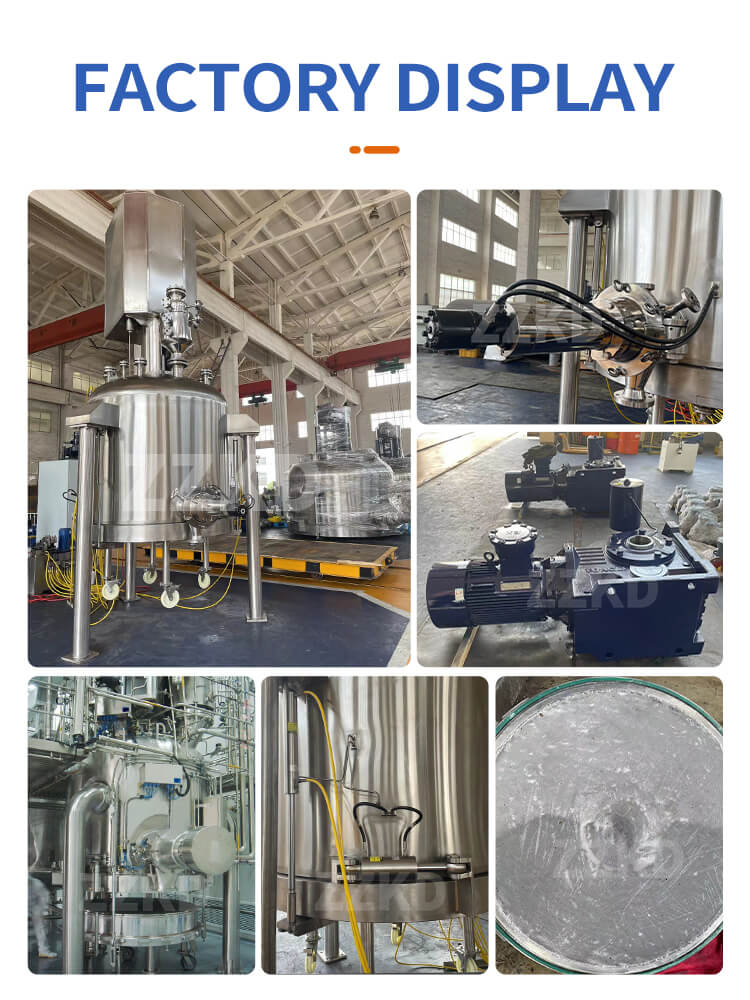

The Agitated Nutsche Filter Dryer, with its remarkable capabilities, exemplifies the innovation and dedication to quality embodied by companies like ZZKD Machinery and Instrument Equipment Co., Ltd. As suppliers of high-quality equipment, ZZKD continues to contribute to the success of industries worldwide, ensuring that cutting-edge technology like the Agitated Nutsche Filter Dryer remains accessible to those who rely on it.