Laboratory glass reactor introduction

A laboratory glass reactor is a device used in scientific research and chemical analysis to carry out reactions and process materials in a controlled environment. It consists of a glass vessel with a stirrer, heating and cooling systems, and ports for adding and removing substances.

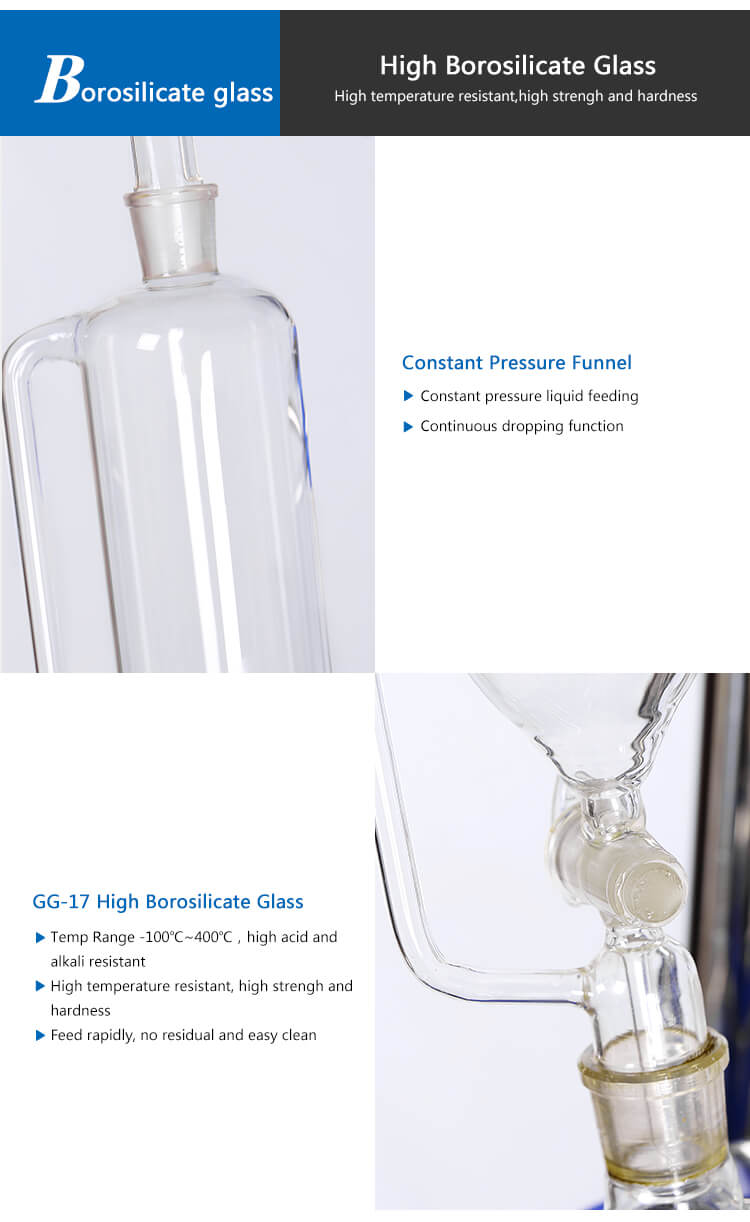

The glass vessel, also called a reaction vessel, is typically made of borosilicate glass, which is resistant to chemical and thermal stress. The stirrer, powered by a motor, is used to mix the materials inside the vessel to ensure uniformity of the reaction. The heating and cooling systems allow the reactor to operate at different temperatures, depending on the needs of the experiment.

The ports on the reactor allow for the addition of reagents or removal of samples during the reaction. These ports may also be used to connect other laboratory equipment such as sensors, probes, and vacuum pumps.

Laboratory glass reactors come in different sizes, ranging from small benchtop models to large-scale industrial versions. They are used in a variety of fields, including pharmaceuticals, petrochemicals, and materials science. Common applications of laboratory glass reactors include chemical synthesis, polymerization, crystallization, and extraction.

Laboratory glass reactors are an essential tool for chemical research and analysis. They offer precise control over reaction conditions, allow for continuous monitoring of the reaction, and provide a safe environment for handling potentially hazardous chemicals.

Laboratory glass reactor Features:

Laboratory glass reactors are versatile and widely used equipment in scientific research and chemical analysis. Some of the key features of laboratory glass reactors include:

Durability: Glass reactors are made of borosilicate glass, which is resistant to thermal and chemical stress, making them durable and long-lasting.

Versatility: Glass reactors can be used for a variety of applications, such as chemical synthesis, crystallization, polymerization, and extraction.

Control over reaction conditions: The ability to control and adjust the reaction temperature, stirring speed, and other parameters makes glass reactors a popular choice for researchers who require precise control over reaction conditions.

Observation of the reaction: Glass reactors are transparent, allowing for real-time observation of the reaction and changes in the material being processed. This feature is particularly important in applications such as crystallization.

Safety: Glass reactors provide a safe environment for handling hazardous chemicals as they are resistant to corrosion and do not react with most chemicals.

Customization: Glass reactors can be customized to meet specific experimental needs, such as adding additional ports, modifying the stirring system, or adjusting the vessel size.

Easy maintenance: Glass reactors are easy to clean and maintain, which is important for ensuring accurate and repeatable results in research.

Laboratory glass reactors offer a range of features that make them an essential tool for scientific research and chemical analysis. Their durability, versatility, control over reaction conditions, and safety features make them a popular choice for a wide range of applications.

Laboratory glass reactor Application:

Laboratory glass reactors find numerous applications in various fields of scientific research and chemical analysis. Some common applications include:

Chemical Synthesis: Glass reactors are widely used for chemical synthesis, ranging from small-scale benchtop reactions to large-scale industrial production. They provide precise control over reaction conditions, allowing researchers to optimize reaction parameters and study reaction kinetics.

Polymerization: Polymerization reactions, which involve the formation of polymers from monomers, are often carried out in glass reactors. Glass reactors allow for controlled heating, stirring, and monitoring of the polymerization process, enabling researchers to study polymerization kinetics, molecular weight distribution, and other polymer properties.

Crystallization: Glass reactors are commonly used for crystallization processes, where a solid crystalline material is formed from a solution or melt. The transparency of glass reactors allows for real-time observation of crystal formation, growth, and morphology, which is important for studying crystallization kinetics and optimizing crystal quality.

Extraction: Glass reactors are used for extraction processes, such as solid-liquid extraction or liquid-liquid extraction, to separate components from a mixture. The controlled heating and stirring in glass reactors aid in efficient extraction processes, making them ideal for extraction experiments.

Process Optimization: Glass reactors are utilized in process development and optimization, where researchers can study the effects of different reaction conditions on the process performance. This helps in identifying the optimal reaction parameters for scaling up a process to a larger scale.

Material Science: Glass reactors are employed in materials science research, such as synthesis of nanoparticles, thin films, and composites. The precise control over reaction conditions in glass reactors allows for the synthesis and characterization of novel materials with tailored properties.

Environmental Science: Glass reactors are used in environmental science research to study various environmental processes, such as degradation of pollutants, water treatment, and waste treatment. The controlled environment provided by glass reactors enables researchers to simulate and study environmental processes in a controlled and reproducible manner.

Laboratory glass reactors have wide-ranging applications in scientific research and chemical analysis, providing a controlled environment for conducting experiments, optimizing processes, and studying various chemical and physical phenomena.

Supporting Equipment for Laboratory glass reactor:

DLSB-100/30 Refrigerated Circulator

Storage Volume: 100L

Low temperature range: -30℃~RT

Refrigeration capacity: 468~13025W

Rated Power: 4135W

SHZ-C Water Circulating Vacuum Pump

Power: 370W

Flow(L/min): 80

Lift(m): 12

Max.Vacuum(Mpa): 0.098

Tank Capacity: 50L

Case : ZZKD Company Selling Laboratory glass reactor to a Mexican Customer

ZZKD company recently sold a 50L laboratory glass reactor to a Mexican customer, a research institute specializing in materials science. The customer had previously been using smaller glass reactors for their research, but as their projects grew in scale, they needed a larger and more versatile reactor.

The ZZKD team worked closely with the customer to understand their specific needs and requirements for the reactor. They recommended the 50L glass reactor, which was equipped with a powerful motor, efficient heating and cooling systems, and a range of ports for easy sample handling.

After the customer received the reactor, they were impressed with the quality of the product and the excellent customer service provided by ZZKD. They found the reactor easy to use and appreciated the precise control over reaction conditions it provided. The transparent glass vessel also allowed for real-time observation of the reaction, which was particularly helpful in their research on crystallization.

The customer was also pleased with the durability and safety features of the reactor, which made it suitable for handling hazardous chemicals. They found the reactor easy to clean and maintain, which was important for ensuring accurate and reliable results in their research.

Overall, the customer was extremely satisfied with the 50L laboratory glass reactor and the service provided by ZZKD. They expressed their gratitude for the support and expertise provided by the ZZKD team, and would highly recommend the company to other researchers in the field.