Fruit freeze dryer machine introduction

A fruit freeze dryer machine is a piece of equipment used to preserve fruits by removing water from them. The process involves freezing the fruits and then subjecting them to a vacuum, which causes the water to sublimate (change from a solid to a gas state without passing through the liquid phase), leaving behind the dried fruit.

Freeze drying helps to preserve the flavor, color, and nutritional value of fruits, making it a popular method of food preservation. Freeze-dried fruits are often used in the production of snack foods, desserts, and other food products.

Fruit freeze dryer machines come in various sizes, from small tabletop models to large industrial-scale units. They typically consist of a chamber for holding the fruits, a refrigeration system for freezing the fruits, a vacuum pump for creating a vacuum, and a heating system for removing the water from the fruits.

Fruit freeze dryer machines are easy to operate and offer a reliable and efficient way to preserve fruits for long-term storage. They are commonly used in the food industry, as well as by individuals who want to preserve their own fruits at home.

Fruit freeze dryer machine Features:

Here are some common features of a fruit freeze dryer machine:

- Freeze-drying chamber: This is the main compartment of the machine where the fruits are placed for the drying process.

- Vacuum pump: The vacuum pump is responsible for creating a vacuum inside the chamber, which helps to remove the moisture from the fruits.

- Refrigeration system: The refrigeration system is used to cool the chamber and freeze the fruits before the drying process begins.

- Heating system: The heating system is used to raise the temperature of the chamber and the fruits, which helps to sublimate the water.

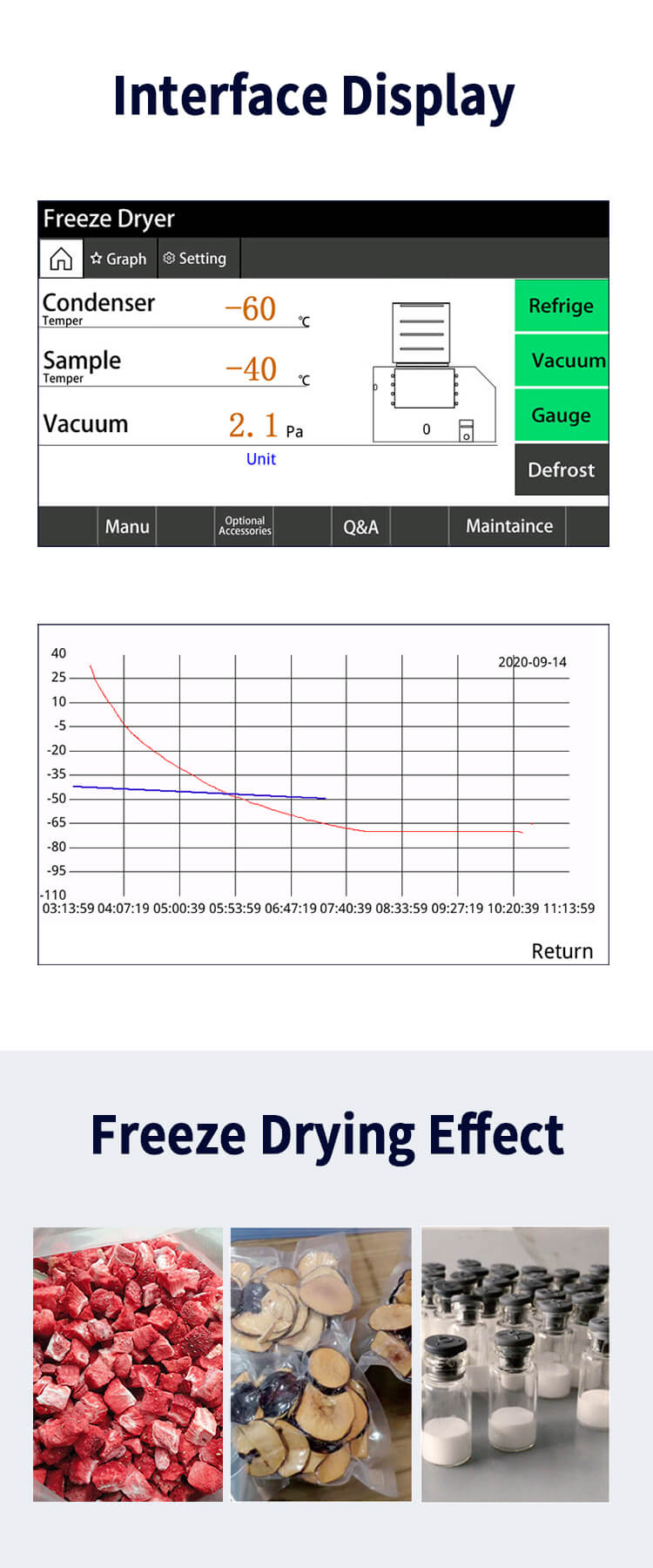

- Control panel: The control panel is used to set the temperature, pressure, and other parameters required for the drying process.

- Stainless steel construction: Many fruit freeze dryer machines are made of high-quality stainless steel, which is durable and easy to clean.

- Various tray configurations: Some machines come with multiple trays, allowing for a larger capacity of fruits to be dried at once.

- Automatic shut-off: Some models have an automatic shut-off feature that turns off the machine when the drying process is complete.

- Data logging: Some advanced models have data logging features that record the drying process parameters, which can be useful for quality control and troubleshooting.

The features of a fruit freeze dryer machine will vary depending on the model and manufacturer, but the above-listed features are some of the most common.

Fruit freeze dryer machine Application:

Fruit freeze dryer machines are widely used in various industries and applications. Here are some common applications of fruit freeze dryer machines:

- Food Industry: Freeze-dried fruits are used in the production of various food products, such as snack foods, desserts, and cereals. Freeze-drying helps to preserve the flavor and nutritional value of fruits, making them a popular ingredient in the food industry.

- Agriculture: Fruit freeze dryer machines are used by farmers and growers to preserve fruits for long-term storage. Freeze-drying helps to prevent spoilage and mold growth, which can occur during traditional drying methods.

- Pharmaceutical Industry: Freeze-drying is also used in the pharmaceutical industry to preserve medicines and vaccines. Freeze-drying helps to stabilize the drugs and extend their shelf life.

- Research and Development: Fruit freeze dryer machines are used in research and development laboratories to study the effects of different drying conditions on fruits. This helps to optimize the drying process and improve the quality of the dried fruits.

- Home Use: Some individuals also use fruit freeze dryer machines for home use. They can be used to preserve excess fruit from the garden or to create healthy snacks for the family.

Fruit freeze dryer machines are versatile and can be used in a wide range of applications across various industries.

Case : ZZKD Company Selling Fruit freeze dryer machine to a Filipino Customer

ZZKD Company is a leading manufacturer of fruit freeze dryer machines, and it recently sold one of its machines to a customer in the Philippines. The customer, a small-scale fruit farmer, was looking for a way to preserve his fruits for longer periods, especially during the off-season when there is a surplus of fruits. After some research, he found ZZKD Company and was impressed with the quality of their machines.

The customer reached out to ZZKD Company through their website and was immediately connected with a sales representative. The sales representative took the time to understand the customer’s needs and recommended a fruit freeze dryer machine that would suit his requirements.

The customer was particularly impressed with the machine’s stainless steel construction, which he believed would make it easy to clean and maintain. The customer also appreciated the automatic shut-off feature that would prevent over-drying and save energy.

After purchasing the machine, the customer received prompt delivery and installation support from ZZKD Company. The sales representative also provided the customer with detailed instructions on how to operate the machine and troubleshoot any issues that might arise.

The customer used the machine to dry various fruits, including mangoes, pineapples, and bananas. He was pleased with the quality of the dried fruits, which retained their flavor and nutritional value. The customer also noted that the dried fruits had a longer shelf life and could be stored for up to a year without spoiling.

In a feedback survey, the customer expressed his satisfaction with the product and the customer service provided by ZZKD Company. He stated that the machine had exceeded his expectations and had helped him to expand his business by allowing him to sell dried fruits year-round. He also appreciated the prompt delivery and installation, as well as the after-sales support provided by the sales representative.

Overall, the sale of the fruit freeze dryer machine to the Filipino customer was a success for ZZKD Company. The customer’s satisfaction with the product and customer service reflects positively on the company’s reputation and commitment to quality.