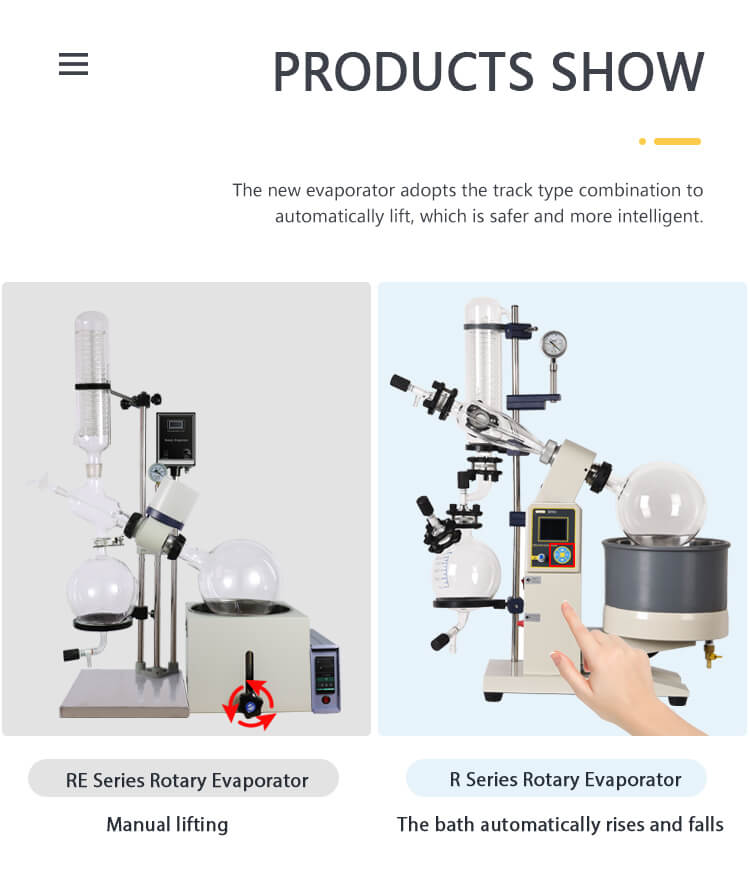

Introduction to Lift Rotary Evaporator

Lift rotary evaporator have revolutionized solvent removal and separation processes in modern laboratories. These devices stand out for their operational efficiency, precision, and user-friendly design, making them indispensable in research and analytical settings.

The Evolutionary Path

The journey of lift rotary evaporators from simple distillation units to advanced, automated systems reflects a significant leap in laboratory technology. Initially designed for basic solvent recovery, these evaporators have evolved into complex instruments capable of precise control and efficient operation, accommodating a wide range of applications in scientific research.

Breakthroughs in Technology

Modern rotovap price incorporate a myriad of technological enhancements. From digital temperature control to automated lift mechanisms, these improvements have streamlined the evaporation process. Innovations such as vacuum control and programmable sequences have further simplified operations, enabling researchers to achieve more accurate results with minimal manual intervention.

Core Components and Lift Rotary Evaporator Impact

Each component of a lift rotary evaporator plays a crucial role in its overall functionality.

The Rotary Flask: Heart of the System

The rotary flask, central to the device, is where the liquid sample is placed. As the flask rotates, it creates a thin film of the liquid over the surface, which aids in efficient and uniform evaporation. This rotation, combined with a heated water bath, accelerates the evaporation process, ensuring quick and effective solvent removal.

The Condenser: Ensuring Efficient Recovery

The condenser in a lift rotary evaporator is key to recovering the evaporated solvent. As the vapor rises from the rotary flask, it enters the condenser, where it cools and reverts to a liquid state. This recovered solvent collects in a separate flask, allowing for its reuse or disposal as per the experimental requirements.

Operational Mechanics in Detail

The lift rotary evaporator operates through a series of well-orchestrated steps.

The Process of Evaporation

Upon starting the device, the rotary flask containing the sample begins to rotate. Simultaneously, the water bath heats up, causing the solvent in the sample to evaporate. The rotation of the flask spreads the sample into a thin film, facilitating rapid evaporation. The vacuum system inside the evaporator lowers the boiling point of the solvent, speeding up the process while preventing overheating of sensitive substances.

Control Mechanisms

Operators can control various aspects of the evaporation process, such as the rotation speed of the flask, the temperature of the water bath, and the vacuum level. These controls enable customization of the evaporation process, accommodating different solvents and sample types.

Safety Measures and Maintenance Practices

Operating a lift rotary evaporator requires adherence to safety protocols and regular maintenance.

Safety First

Safety features of lift rotary evaporators include overheating protection, spillage prevention, and automatic shutdown mechanisms in case of abnormal operations. Users must always wear appropriate personal protective equipment and follow laboratory safety guidelines when operating the device.

Maintenance for Longevity

Regular maintenance, including cleaning the rotary flask, condenser, and water bath, and checking for any wear and tear on seals and joints, is essential for ensuring the longevity and reliability of the evaporator.

Looking Toward the Future

The future of lift rotary evaporators holds promise for even more sophisticated and automated systems.

Innovations Ahead

Emerging technologies, such as AI-driven control systems and advanced materials for better heat transfer and durability, are anticipated to further enhance the capabilities of lift rotary evaporators.

Conclusion: Partnering with ZZKD

In conclusion, the lift rotary evaporator represents a significant advancement in laboratory technology. ZZKD Machinery and Instrument Equipment Co., Ltd. offers a range of high-quality lift rotary evaporators, embodying the company’s commitment to innovation and excellence.

Step Forward with ZZKD

For laboratories seeking to enhance their capabilities, partnering with ZZKD provides access to state-of-the-art equipment and expert support. Visit the ZZKD website to explore their range of lift rotary evaporators and discover how these devices can revolutionize your laboratory operations. With their extensive experience and dedication to customer satisfaction, ZZKD stands as a trusted partner in scientific advancement.