In the dynamic world of chemical processing and laboratory experimentation, the pursuit of safety and efficiency is an unending journey. The 50 liter rotovap at the forefront of this quest, embodying a technological leap that ensures both safety and precision in distillation processes. This article delves deep into the realm of explosion-proof rotary evaporators, elucidating their significance, multifaceted applications, and tangible benefits. A real-world case study will underscore their transformative impact on chemical extraction and purification.

Evolution of Laboratory Distillation: From Tradition to Innovation

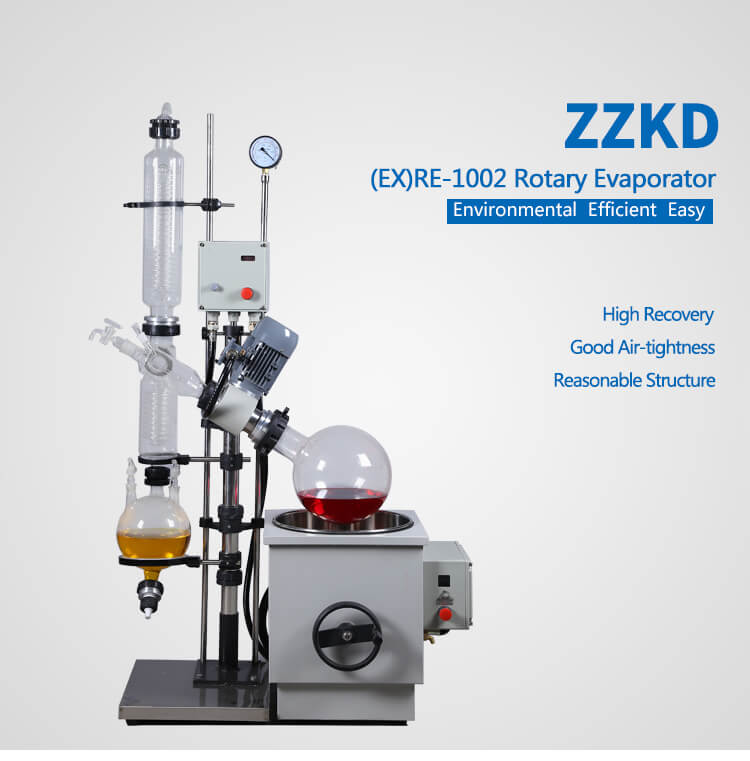

At the heart of modern laboratory advancements lies the explosion-proof rotary evaporator, an intricate instrument that redefines the landscape of chemical distillation. Beneath its sleek façade lies a meticulously crafted array of engineering marvels, meticulously calibrated for enhanced safety and efficiency.

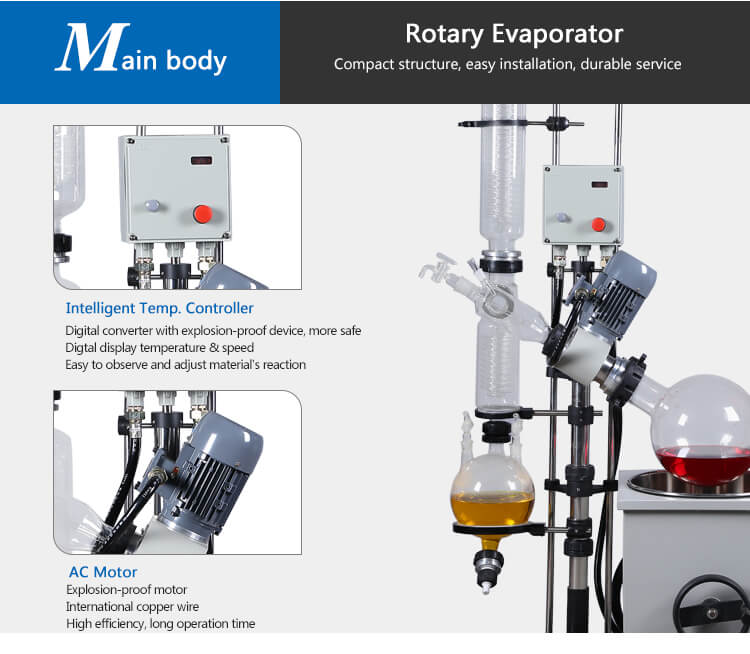

Contrary to conventional rotary evaporators, the explosion-proof variant emerges as a paragon of ingenuity, seamlessly integrating the principles of heat, vacuum, and rotational force. This orchestration of elements facilitates the separation and concentration of substances with unprecedented precision. However, the true distinction of the explosion-proof rotary evaporator lies in its formidable safety features, addressing the critical exigencies of working with flammable and explosive solvents.

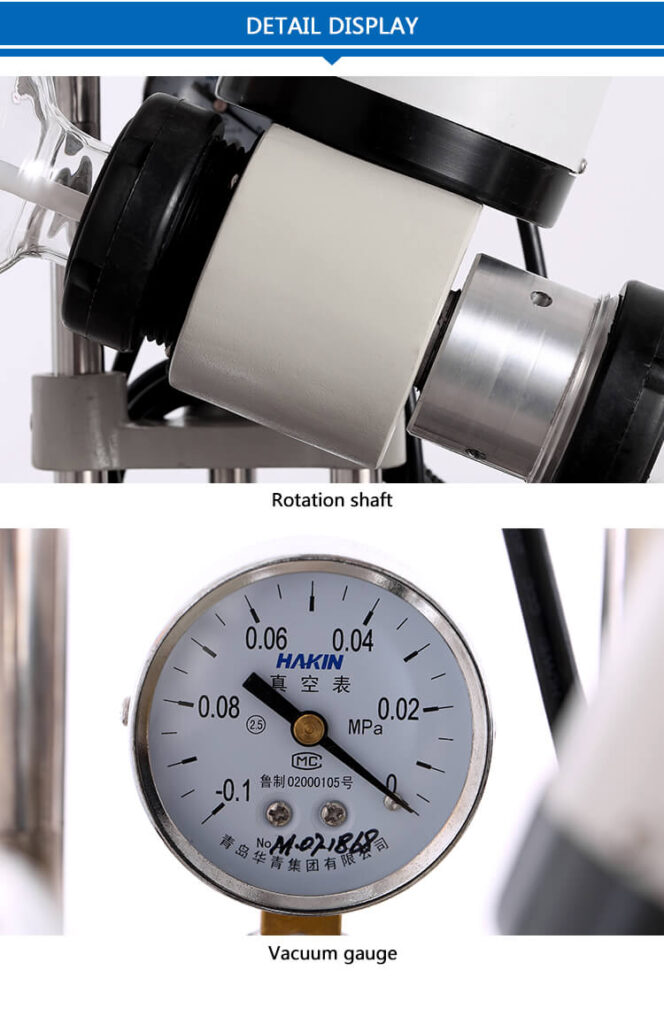

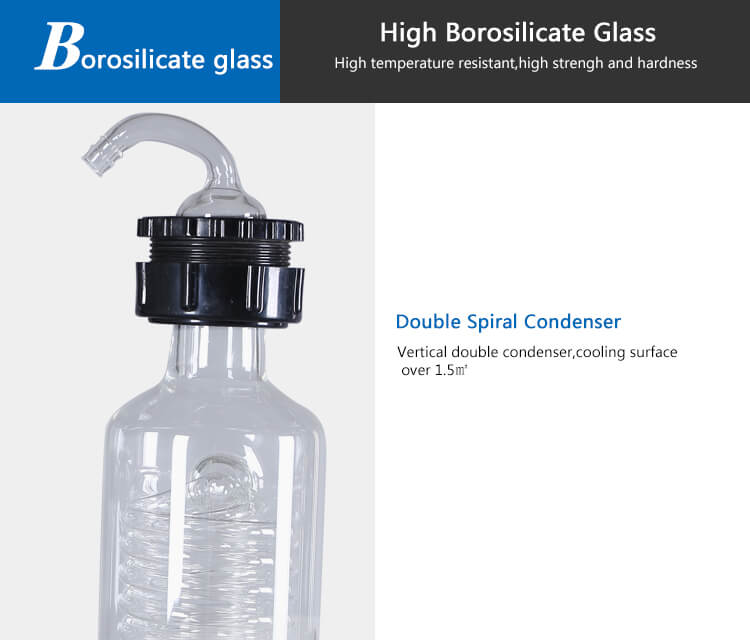

The backbone of this safety apparatus is its construction. Engineered from flameproof materials, the rotary evaporator acts as a robust citadel, capable of containing internal explosions, should they occur. This impermeable barrier ensures that potential hazards remain confined within the equipment, safeguarding the laboratory environment and its occupants. Furthermore, meticulous seals and advanced ignition-prevention mechanisms fortify the device, preempting any catalyst for ignition.

Understanding the Explosion Proof Rotary Evaporator: A Technological Marvel

At its core, the explosion proof rotary evaporator is an intricate apparatus engineered to facilitate meticulous separation and concentration of substances. While traditional rotary evaporators are adept at this task, the explosion-proof variant distinguishes itself through enhanced safety parameters. Its robust construction, specialized seals, and advanced ignition-prevention mechanisms render it suitable for environments replete with flammable or explosive solvents.

Applications Across Industries: Where Safety Meets Distillation

The explosion proof rotary evaporators assumes a versatile role, transcending industry boundaries to become an indispensable tool. Whether empowering pharmaceutical research, enabling intricate chemical synthesis, extracting precious essential oils, or optimizing food and beverage production, this equipment finds its place in diverse sectors. Its adaptability to a myriad of solvents and compounds underscores its indispensability.

A Spotlight on Safety: How Explosion Proof Rotary Evaporator Design Works

The cornerstone of the explosion-proof rotary evaporator’s efficacy is its meticulously crafted design, intended to neutralize potential hazards. Comprising flameproof materials, this apparatus contains internal explosions, averting catastrophic consequences. Furthermore, vigilantly regulated vacuum and temperature controls preclude conditions conducive to ignition. Such meticulous safety features encapsulate the ingenuity behind this revolutionary equipment.

Realizing Efficiency: Benefits of Using an Explosion Proof Rotary Evaporator

Beyond its safety prowess, the explosion proof rotary evaporator delivers a gamut of benefits that synergize to elevate operational efficiency and overall productivity. The fine-tuned management of temperature and pressure engenders optimized distillation processes, culminating in augmented yields and heightened purity of end products. The equipment’s judicious automation curtails the necessity for constant manual intervention, affording researchers the liberty to channel their efforts toward other critical tasks.

Application Case: Elevating Aromatic Oil Extraction in the Perfume Industry

A compelling illustration of the explosion proof rotary evaporator’s transformative potential transpires within the realm of perfume manufacturing. Extracting precious aromatic compounds from delicate natural sources had long posed intricate challenges. Traditional methods, reliant on flammable solvents, not only jeopardized safety but also compromised aromatic quality. In a striking instance, a prominent French perfume house harnessed the innovation of the explosion proof rotary evaporators to revolutionize their processes.

Confronted with the task of extracting essential oils from fragile flower petals, the perfume manufacturer grappled with perilous fire risks inherent to conventional distillation. The adoption of an explosion proof rotary evaporator marked a paradigm shift. Robust safety parameters enabled the use of flammable solvents, devoid of peril. This pivotal transition not only fortifying safety but also boosting oil yields and enhancing aromatic profiles, thereby amplifying the olfactory allure of their perfumes.

Looking Ahead: Innovations and Advancements in Safety Technology

The trajectory of laboratory equipment innovation marches ever forward, continuously amplifying safety thresholds. The explosion proof rotary evaporators stands as an emblematic vanguard in this pursuit. The crucible of research and engineering ceaselessly churns, yielding novel materials, intelligent automation, and refined control systems. The impending landscape promises a veritable renaissance in safety and efficiency standards, reshaping the contours of chemical processing.

Conclusion

The explosion proof rotary evaporator, an epitome of human ingenuity, coalesces safety and innovation into a singular entity. Its indispensability in contemporary laboratory practices, coupled with its sweeping applicability across industries, underscores its pivotal role in chemical distillation. A tangible testament to its transformative prowess surfaces through a resonant case study within the perfume industry, spotlighting its capability to metamorphose processes while harmonizing safety and productivity. As technology’s march persists, the explosion proof rotary evaporator propels us toward a future wherein hazardous processes unravel with resolute confidence, charting new milestones in chemical processing’s safety and efficiency tapestry.