Stainless steel chemical reactor introduction

A stainless steel chemical reactor is a vessel used for carrying out chemical reactions. It is made of high-quality stainless steel and is designed to withstand high temperatures and pressures. Stainless steel is preferred for making chemical reactors because of its excellent resistance to corrosion, durability, and low maintenance cost.

Chemical reactors are used in a variety of industries, including pharmaceuticals, chemicals, petrochemicals, food processing, and many more. They can be used for a wide range of reactions, including polymerization, oxidation, hydrogenation, and many other chemical processes.

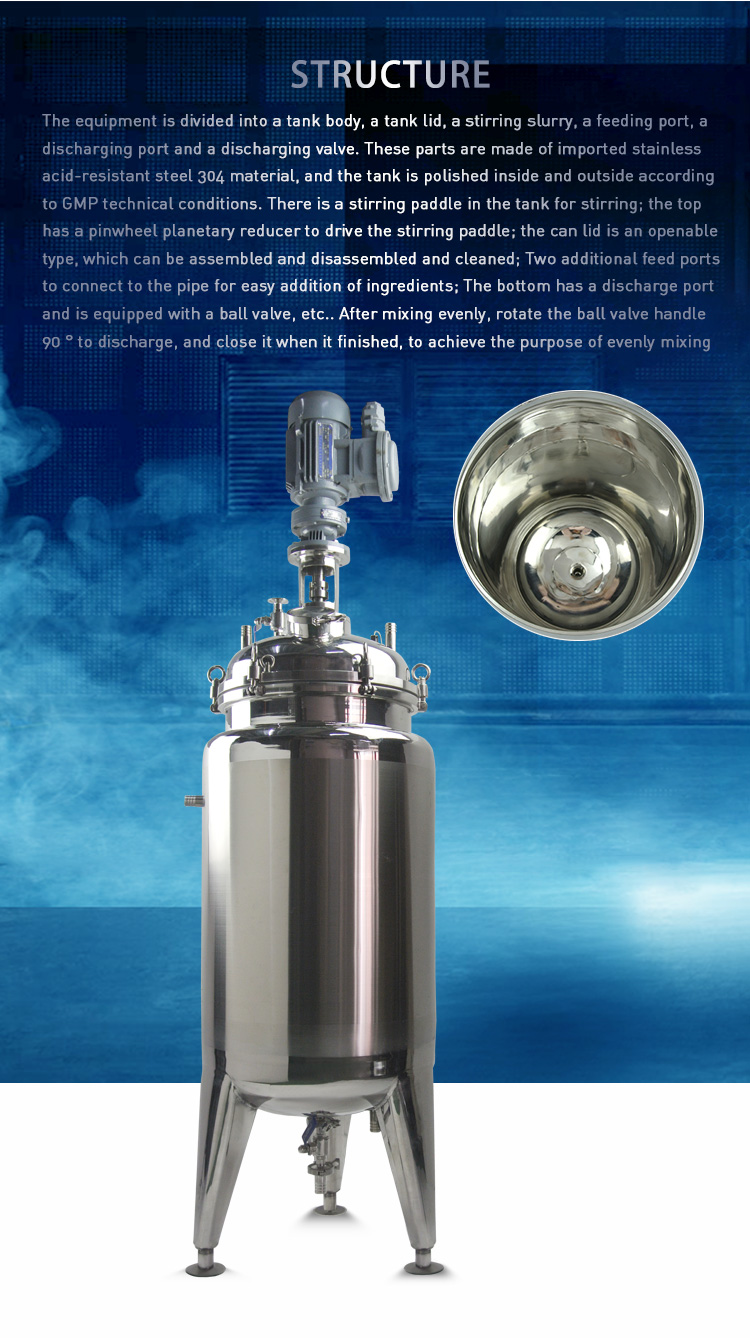

The design of a stainless steel chemical reactor will depend on the specific application and the reaction being carried out. Typically, it will include features such as a heating or cooling system, agitation, a means of measuring temperature and pressure, and safety features such as relief valves.

In addition to the design of the reactor itself, it is important to consider the materials used for the internal components, such as the agitator, baffles, and inlet/outlet connections. These materials must be compatible with the chemicals being used and must be able to withstand the conditions of the reaction.

Stainless steel chemical reactor is an essential tool for conducting chemical reactions on an industrial scale. Its design and construction must be carefully considered to ensure safety, reliability, and optimal performance.

Stainless steel chemical reactor Features:

Stainless steel chemical reactors are designed with several features that make them suitable for a variety of chemical processes. Here are some of the key features of stainless steel chemical reactors:

- Material: Stainless steel chemical reactors are made of high-quality stainless steel, which provides excellent corrosion resistance, durability, and ease of maintenance.

- Heating and cooling system: Most stainless steel chemical reactors are designed with a heating and cooling system to maintain the desired temperature during the reaction. This can be achieved using a jacket around the reactor or internal coil.

- Agitation: Agitation is used to improve mixing and ensure uniform reaction throughout the vessel. Stainless steel chemical reactors are designed with various types of agitators such as paddle, turbine, anchor, or propeller.

- Pressure and temperature measurement: Stainless steel chemical reactors are equipped with pressure and temperature sensors to monitor and control the reaction conditions.

- Inlet/outlet connections: Inlet and outlet connections are provided for adding and removing reactants and products from the reactor.

- Safety features: Safety features such as relief valves and rupture disks are installed to prevent overpressure situations and ensure safe operation.

- Cleaning and maintenance: Stainless steel chemical reactors are designed for easy cleaning and maintenance to minimize downtime and maximize productivity.

- Customization: Stainless steel chemical reactors can be customized to suit specific application requirements such as size, shape, and design.

The features of stainless steel chemical reactors make them a versatile and reliable tool for carrying out a wide range of chemical processes.

Stainless steel chemical reactor Application:

Stainless steel chemical reactors are used in a variety of industries for carrying out various chemical processes. Here are some common applications of stainless steel chemical reactors:

- Chemical industry: Stainless steel chemical reactors are used in the chemical industry for various processes such as polymerization, hydrogenation, oxidation, and other reactions.

- Pharmaceutical industry: The pharmaceutical industry uses stainless steel chemical reactors for manufacturing drugs, including synthesis, crystallization, and purification processes.

- Petrochemical industry: The petrochemical industry uses stainless steel chemical reactors for processes such as cracking, polymerization, and distillation.

- Food and beverage industry: Stainless steel chemical reactors are used in the food and beverage industry for processes such as fermentation, mixing, and extraction.

- Environmental industry: The environmental industry uses stainless steel chemical reactors for processes such as wastewater treatment, bioremediation, and chemical processing.

- Research and development: Stainless steel chemical reactors are used in research and development laboratories for studying chemical reactions, developing new products, and optimizing reaction conditions.

Stainless steel chemical reactors are essential tools for a wide range of industries that require reliable and efficient chemical processing equipment. Their versatility and ability to be customized to specific application requirements make them an ideal choice for many chemical processes.

Case : ZZKD Company Selling Stainless steel chemical reactor to a Brazilian Customer

ZZKD is a leading manufacturer of stainless steel chemical reactors, providing high-quality and reliable solutions for various industries around the world. Recently, the company sold a stainless steel chemical reactor to a customer in Brazil, and the customer was extremely satisfied with the product and service provided by ZZKD.

The Brazilian customer was a leading pharmaceutical company that specializes in the development and manufacturing of drugs. They required a high-quality stainless steel chemical reactor for their drug synthesis process, which required precise temperature and pressure control, as well as high levels of agitation for efficient mixing.

ZZKD provided the customer with a customized stainless steel chemical reactor that met their specific requirements. The reactor was designed with a heating and cooling system, agitator, pressure and temperature sensors, and inlet/outlet connections, all made of high-quality stainless steel for optimal performance and durability.

The customer was very pleased with the performance of the stainless steel chemical reactor, which allowed them to carry out their drug synthesis process with high efficiency and precision. They were impressed with the quality of the product and the level of support provided by ZZKD throughout the entire process, from design to delivery.

The customer provided positive feedback on ZZKD’s excellent customer service and prompt response to their inquiries. They were also impressed with the technical support provided by ZZKD’s engineers, who were able to provide valuable insights and guidance on the use and maintenance of the stainless steel chemical reactor.

In summary, ZZKD’s sale of a stainless steel chemical reactor to a Brazilian pharmaceutical customer was a success, with the customer expressing high levels of satisfaction with the product and service provided. This case exemplifies ZZKD’s commitment to providing high-quality, customized solutions for their customers, and their dedication to providing excellent customer service and support.