Jacketed stainless steel reactor introduction

A jacketed stainless steel reactor is a type of vessel used for chemical reactions that require precise temperature control. It is a cylindrical vessel with a jacketed outer shell, which is used to circulate heating or cooling fluids around the inner vessel. The inner vessel, which is made of stainless steel, is where the reaction takes place.

The jacketed design allows for the precise control of temperature within the reactor, which is essential for many chemical processes. Heating or cooling fluids can be circulated through the jacket, allowing for rapid changes in temperature when necessary. The jacket can also be used to maintain a constant temperature throughout the reaction, which is critical for reactions that are sensitive to temperature changes.

Jacketed stainless steel reactors are commonly used in the pharmaceutical, chemical, and food industries for a variety of processes, including mixing, blending, fermentation, and chemical reactions. They are available in a range of sizes, from small laboratory-scale vessels to large industrial reactors, depending on the specific needs of the application.

Jacketed stainless steel reactor Features:

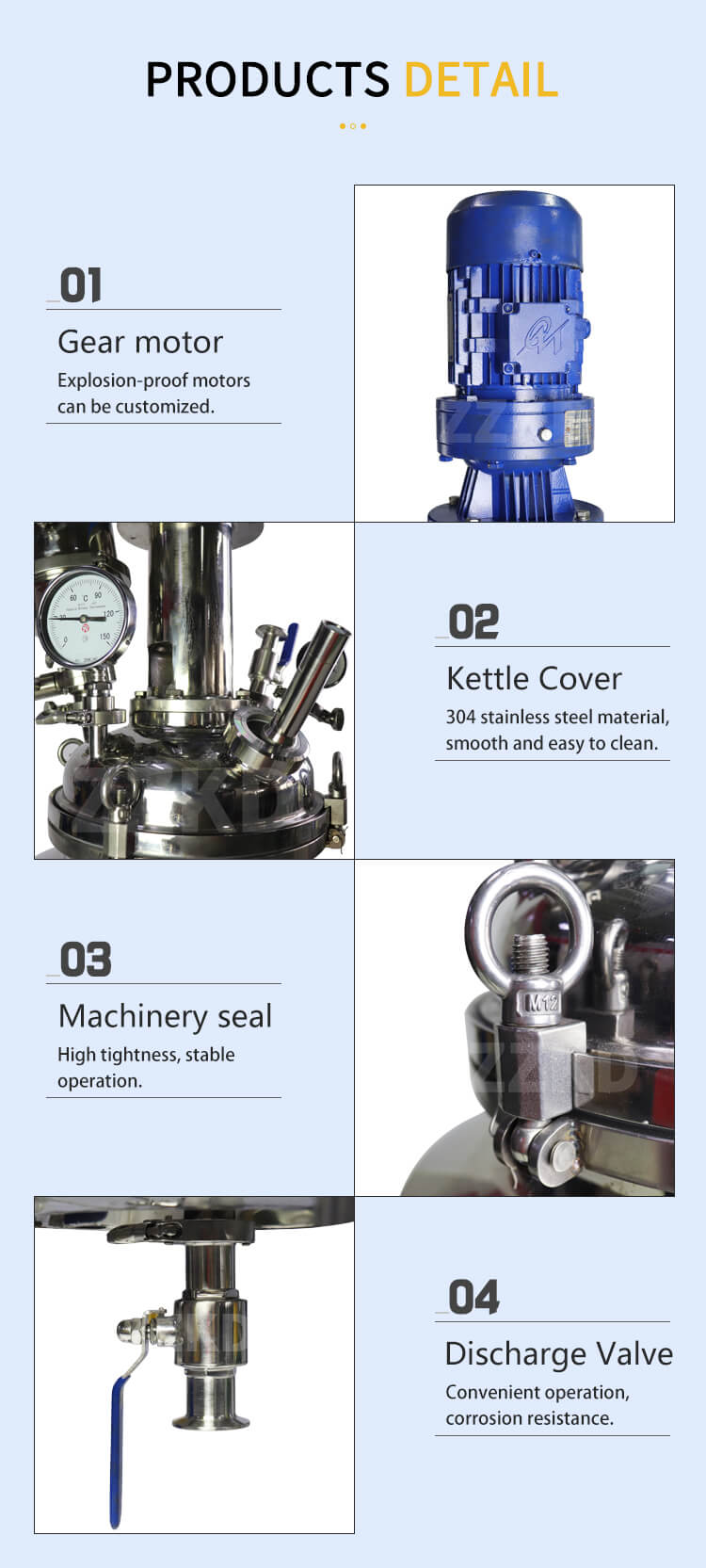

Some key features of a jacketed stainless steel reactor are:

- Material: The inner vessel of the reactor is made of stainless steel, which is highly resistant to corrosion, making it suitable for use with a wide range of chemicals.

- Jacket: The outer shell of the reactor is jacketed, which allows for precise temperature control during the reaction.

- Temperature control: The jacket allows for the circulation of heating or cooling fluids, which enables precise temperature control within the reactor.

- Pressure control: Many jacketed stainless steel reactors are designed to handle high pressure, making them suitable for a wide range of chemical reactions.

- Mixing: The reactor can be equipped with various mixing systems, such as agitators or impellers, to ensure efficient mixing of the reaction components.

- Sampling: The reactor can be equipped with sampling ports, which allow for the monitoring of the reaction progress and the collection of samples.

- Cleaning: Stainless steel is easy to clean and sterilize, making it ideal for use in the pharmaceutical and food industries.

- Customization: Jacketed stainless steel reactors can be customized to meet specific requirements, such as size, shape, and features, depending on the specific needs of the application.

Jacketed stainless steel reactor Application:

Jacketed stainless steel reactors are used in a wide range of applications in the chemical, pharmaceutical, and food industries. Some of the most common applications include:

- Chemical reactions: Jacketed stainless steel reactors are commonly used for chemical reactions, such as polymerization, hydrogenation, and oxidation, that require precise temperature and pressure control.

- Fermentation: The reactors are used for fermentation processes, such as the production of antibiotics, enzymes, and biopolymers.

- Mixing and blending: Jacketed stainless steel reactors are used for mixing and blending of various components, such as powders, liquids, and gases.

- Crystallization: The reactors can be used for crystallization processes, such as the production of pharmaceuticals and specialty chemicals.

- Distillation: The reactors can be used for distillation processes, such as the purification of solvents and chemicals.

- Food processing: Jacketed stainless steel reactors are used in the food industry for cooking, mixing, and fermentation of various food products.

- Biotechnology: The reactors are used in biotechnology applications, such as the production of biofuels and biomolecules.

Jacketed stainless steel reactors are versatile vessels that can be customized to meet specific requirements and are essential for many industrial processes that require precise temperature and pressure control.

Case : ZZKD Company Selling Jacketed stainless steel reactor to a Chilean Customer

ZZKD Company, a leading manufacturer of laboratory and industrial equipment, recently sold a jacketed stainless steel reactor to a Chilean customer. The customer, a research laboratory in Chile, had a critical need for a reliable and high-quality reactor to support their chemical synthesis projects.

The customer reached out to ZZKD Company after conducting extensive research on the best options for a jacketed stainless steel reactor. They were impressed with the company’s reputation for producing high-quality laboratory equipment and its commitment to providing excellent customer service.

After discussing the customer’s specific requirements for the reactor, ZZKD Company recommended their top-of-the-line jacketed stainless steel reactor. The reactor features a double-walled design with an insulating layer, which provides efficient temperature control and reduces the risk of heat loss. Additionally, it is constructed with high-grade stainless steel, making it resistant to corrosion and ensuring long-term durability.

The customer was pleased with the professionalism and expertise of ZZKD Company’s sales team throughout the purchasing process. The team provided clear and detailed information about the reactor’s features and functionality, as well as its maintenance requirements. They also ensured that the reactor was shipped promptly and arrived at the customer’s facility in excellent condition.

After using the jacketed stainless steel reactor for several months, the Chilean customer provided positive feedback about its performance. They noted that the reactor’s temperature control was highly accurate and consistent, allowing for precise control of their chemical reactions. They also appreciated the reactor’s robust design, which provided excellent stability during operation.

Overall, the customer was extremely satisfied with their purchase from ZZKD Company. They praised the company for producing high-quality laboratory equipment that met their specific needs and exceeded their expectations. The customer also noted that they would recommend ZZKD Company to other research laboratories in Chile and around the world.

In conclusion, ZZKD Company’s sale of a jacketed stainless steel reactor to a Chilean customer exemplifies the company’s commitment to producing high-quality laboratory equipment and providing excellent customer service. The customer’s positive feedback about the reactor’s performance is a testament to the company’s expertise and dedication to meeting their customers’ needs.