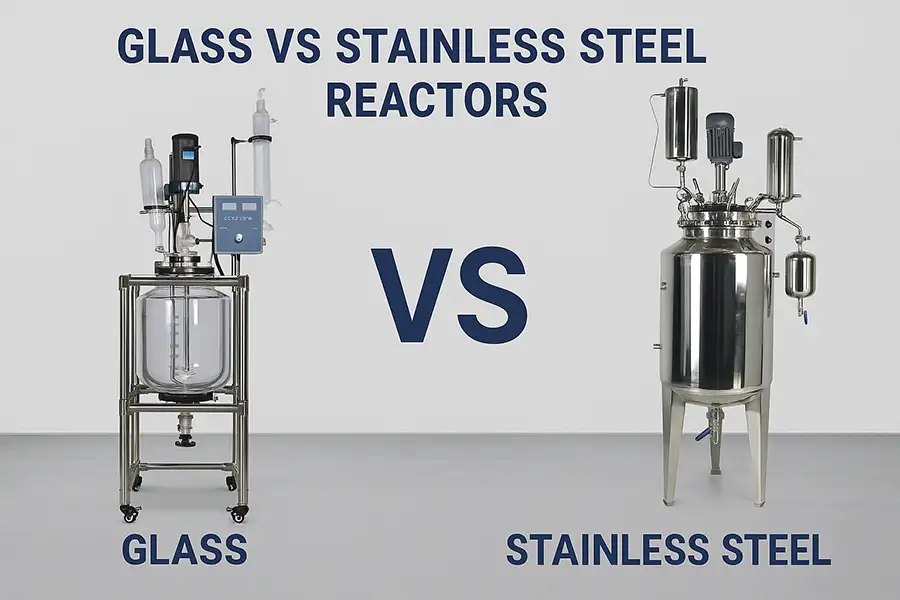

In the chemical processing industry, glass reactor suppliers have long provided equipment for laboratories and pilot-scale operations. Glass reactors are valued for their transparency, chemical resistance, and suitability for low-pressure applications. However, as industrial demands grow, many businesses are turning to stainless steel reactors for their durability, versatility, and scalability.

Understanding Glass Reactors

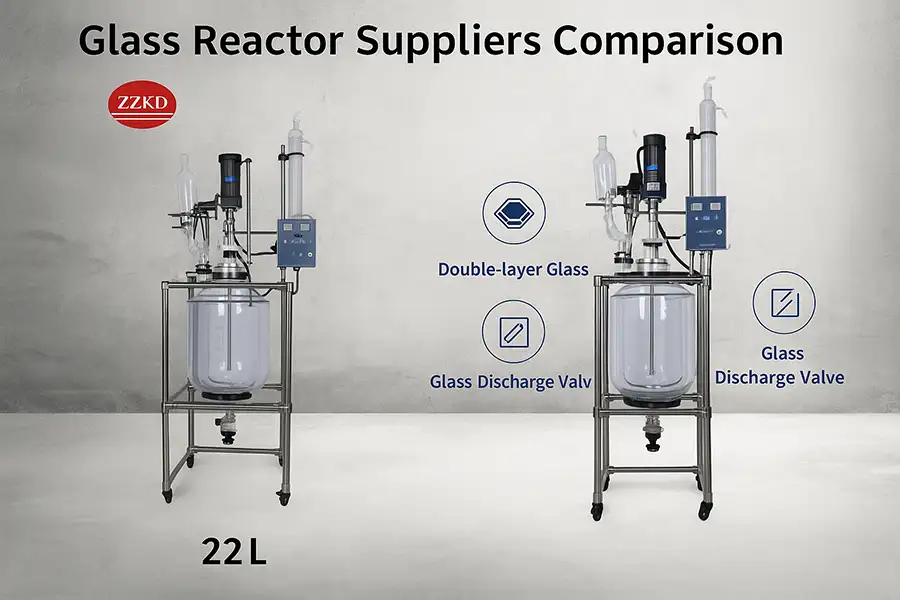

Glass reactors are typically made from borosilicate glass, which offers excellent resistance to thermal shock and chemical corrosion. They are ideal for processes where visibility is important, such as monitoring crystallization or color changes during reactions.

Why do some industries still prefer glass reactors despite the availability of stainless steel options?

Glass reactors allow direct visual monitoring, which is crucial in research and development phases. They are also less expensive for small-scale operations and are easier to clean when working with certain solvents.

Limitations of Glass Reactors

While glass reactors have their benefits, they are not without limitations. They are prone to breakage under mechanical stress, have lower pressure and temperature tolerance, and are less suitable for large-scale production.

Rise of Stainless Steel Reactors

Stainless steel reactors have become the preferred choice for many industrial applications. They can handle high pressures, extreme temperatures, and aggressive chemicals. According to industry data, stainless steel reactors can operate at pressures exceeding 20 bar and temperatures above 300°C, making them ideal for petrochemical, pharmaceutical, and food processing industries.

Could switching from glass to stainless steel reactors improve production efficiency?

Yes. Stainless steel reactors offer faster reaction times due to better heat transfer, can accommodate larger batch sizes, and reduce downtime caused by equipment fragility.

Economic Considerations

Although stainless steel reactors require a higher initial investment, their longevity and ability to handle diverse processes often lead to lower operational costs over time. Based on a 2023 market analysis, companies that switched to stainless steel reactors reported a 15-20% reduction in maintenance expenses.

Authoritative Data Reference

According to a study by the Massachusetts Institute of Technology (MIT), technological advancements, including AI integration in manufacturing, are expected to replace 30% of current industrial jobs by 2030. This shift will further emphasize the need for adaptable and high-performance equipment like stainless steel reactors.

Comparative Table: Glass vs Stainless Steel Reactors

| Feature | Glass Reactor | Stainless Steel Reactor |

|---|---|---|

| Pressure Tolerance | Low (up to ~3 bar) | High (up to 20+ bar) |

| Temperature Range | -80°C to 200°C | -196°C to 350°C |

| Durability | Fragile | Highly durable |

| Scale | Lab & pilot-scale | Lab to full industrial production |

| Cost | Lower initial cost | Higher initial cost, lower lifecycle cost |

Internal Resources

Conclusion

While glass reactor suppliers continue to serve research labs and specialized applications, stainless steel reactors are becoming the backbone of modern industrial chemical processing. Their strength, adaptability, and long-term cost benefits make them a smart investment for companies looking to scale production and improve safety.

Is it worth contacting a supplier to discuss upgrading equipment now?

Absolutely. Early adoption of stainless steel reactors can position a company ahead of competitors, especially as industry regulations and production demands evolve.