Introduction to Methanol Rotary Evaporation

Methanol rotary evaporators, commonly referred to as rotovaps, are a staple in modern laboratories. They are designed for the efficient and gentle removal of solvents from samples, particularly methanol. The role of a methanol rotary evaporator in facilitating various scientific processes is undeniable. These devices are essential for conducting a wide range of experiments, particularly in fields that require the concentration of substances or the removal of solvents under controlled conditions.

In this article, we’ll explore the various aspects of methanol rotary evaporators, including their design, applications, and the factors influencing their price. Understanding these elements is crucial for laboratories and researchers looking to invest in this vital equipment.

Key Components and Features

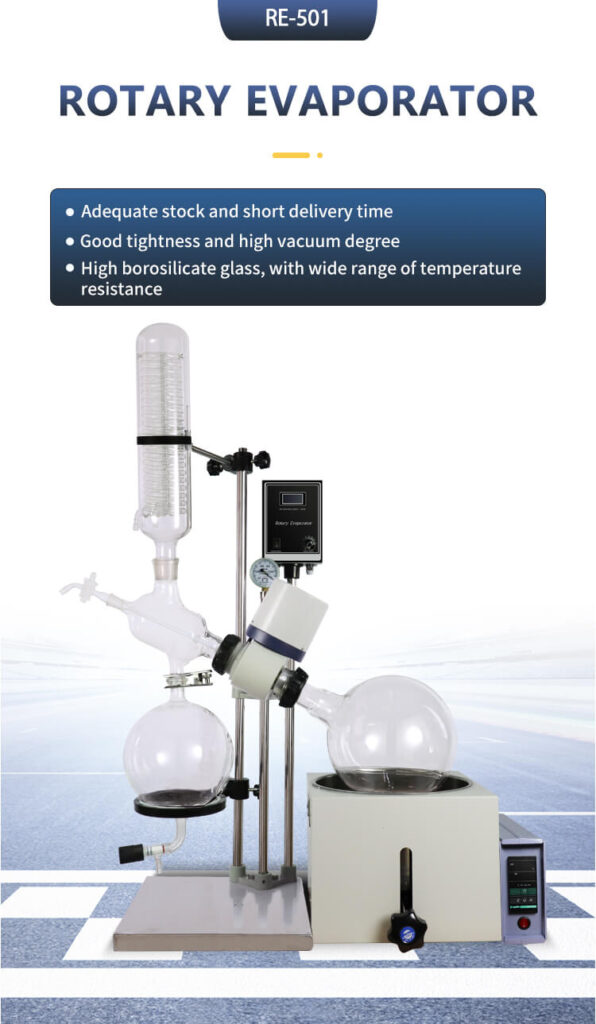

Understanding the components of a methanol rotary evaporator is crucial for its proper utilization. The main elements include the rotating flask, which holds the sample, and the heating bath, which provides the necessary heat to facilitate evaporation. Additionally, a vacuum system is employed to reduce the pressure within the system, and a condenser cools the vapor back to a liquid form, which is then collected.

Each component plays a vital role in the functionality of the evaporator. The rotating flask ensures even heat distribution and efficient evaporation. The heating bath’s temperature can be precisely controlled, which is crucial for delicate operations. The vacuum system enables the reduction of the boiling point of methanol, and the condenser ensures that the evaporated solvent is efficiently recovered, minimizing waste.

Applications in Various Industries

Methanol rotary evaporators have found their place in numerous industries, most notably in pharmaceuticals, chemistry, and environmental sciences. They are critical in processes such as sample preparation, solvent recovery, and purification. In the pharmaceutical industry, for example, they are used in the preparation of samples for analysis and in the purification of compounds.

Similarly, in the field of chemistry, these evaporators are essential for the concentration of solutions and the removal of solvents from reaction mixtures. The environmental science sector benefits from their ability to recover solvents, thereby reducing waste and minimizing the impact on the environment.

Advancements and Innovations

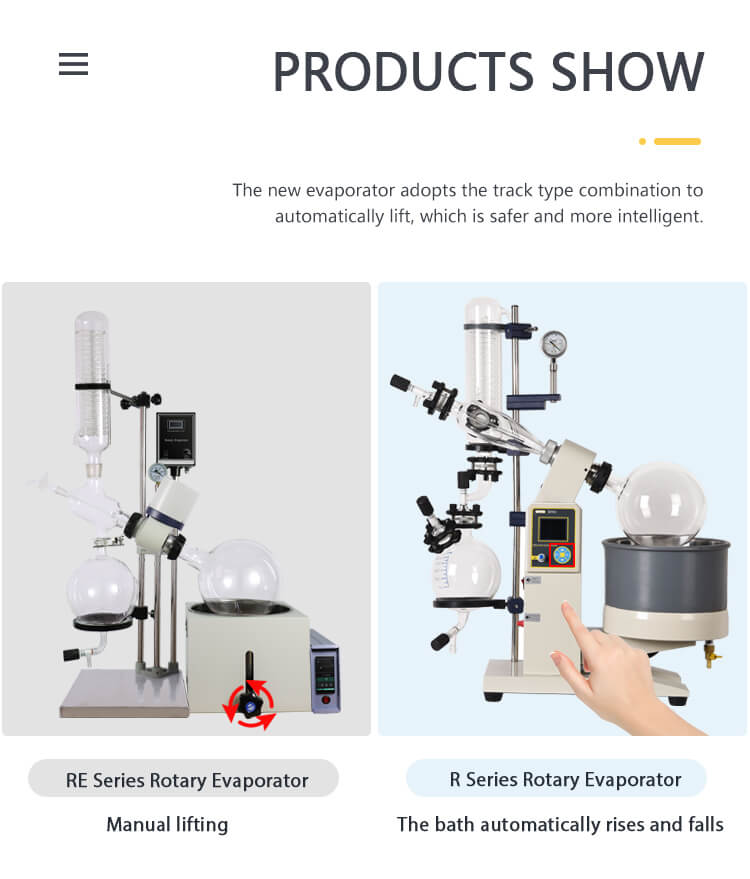

The field of methanol rotary evaporation is not static; it continually evolves with advancements in technology. Recent innovations focus on enhancing user-friendliness, safety, and efficiency. Features such as programmable functions, digital control panels, and automated lifting mechanisms are becoming more common. Safety has also been a significant focus, with newer models featuring over-temperature shut-off and other protective measures.

Energy efficiency is another area where significant strides have been made. Modern methanol rotary evaporators are designed to consume less energy, thereby reducing operational costs and contributing to environmental sustainability.

Understanding the Rotovap Price Factors

The price of a methanol rotary evaporator, or rotovap, can vary widely. This variation is due to factors such as size, capacity, and additional features like digital controls or automated systems. When considering a purchase, it’s essential to balance these factors with the specific needs of your laboratory.

For instance, a larger capacity unit might be necessary for high-volume laboratories, but it will also come at a higher cost. Additional features, while potentially increasing efficiency and ease of use, can also add to the expense. Therefore, understanding the specific requirements of your laboratory is crucial in making a cost-effective decision.

Methanol Rotary Evaporator in Academic Research

In the realm of academic research, methanol rotary evaporators are invaluable. They are particularly prominent in organic chemistry labs, where they are used for tasks such as the concentration of organic compounds and the removal of solvents from reaction mixtures. The precision and efficiency of these devices make them ideal for research purposes, where accuracy and repeatability are crucial.

Moreover, in educational settings, these evaporators are used for teaching students the principles of distillation and solvent removal. This hands-on experience is vital for students pursuing careers in scientific fields, as it provides them with a practical understanding of these fundamental processes.

Benefits in Pharmaceutical Development

The pharmaceutical industry greatly benefits from the precision and efficiency of methanol rotary evaporators. They play a crucial role in the formulation of drugs and in quality control processes. The ability to precisely remove solvents and concentrate substances is essential in ensuring the purity and efficacy of pharmaceutical products.

Furthermore, in the development of new medications, methanol rotary evaporators are used to test small-scale reactions and processes before they are scaled up for production. This ability to test and refine processes at a smaller scale is invaluable in the development of safe and effective pharmaceuticals.

Environmental Impact and Sustainability

In addition to their practical applications, methanol rotary evaporators contribute positively to environmental sustainability. By efficiently recovering solvents, they help reduce waste and the need for new solvent production, which in turn minimizes the environmental impact. This aspect is particularly important in industries where solvent use is extensive, such as in pharmaceuticals and chemistry.

Modern designs focus on reducing energy consumption, further contributing to sustainability efforts. By using less energy, these devices not only reduce operational costs but also lessen the carbon footprint of the laboratories that use them.

Choosing the Right Methanol Rotary Evaporator

Selecting the right methanol rotary evaporator for your laboratory involves considering several factors. The volume of solvent to be evaporated, the boiling point of the solvent, and the specific application requirements are all crucial considerations. Additionally, budget constraints must be balanced with these functional requirements.

For instance, a laboratory that frequently uses high-boiling-point solvents might require an evaporator with a higher temperature range. Similarly, a lab dealing with large volumes of solvent will need an evaporator with a larger capacity. Understanding these needs is key to making an informed and effective purchase.

Maintenance and Safety Tips

Proper maintenance is crucial for the longevity and safe operation of a methanol rotary evaporator. Regular cleaning of the various components, particularly the rotating flask and condenser, is essential. Additionally, components such as seals and gaskets should be inspected regularly and replaced as needed to ensure optimal performance.

Safety is another critical aspect. Methanol rotary evaporators should be used in well-ventilated areas to prevent the buildup of potentially harmful vapors. Following the manufacturer’s guidelines for operation and maintenance is also vital to ensure safe and effective use.

Integration with Other Laboratory Equipment

Methanol rotary evaporators can often be integrated with other laboratory equipment to enhance their functionality. For example, coupling a rotary evaporator with a vacuum pump allows for more precise control over pressure conditions, which can be crucial for certain applications. Similarly, integrating the evaporator with a chiller can improve the efficiency of the condensation process, leading to better solvent recovery.

This ability to integrate with other equipment makes methanol rotary evaporators versatile tools that can be adapted to a wide range of scientific processes, enhancing the overall efficiency of laboratory operations.

The Future of Methanol Rotary Evaporators

Looking to the future, we can expect continued innovation in the field of methanol rotary evaporators. Advances in materials science may lead to more durable and efficient components, while developments in automation could make these devices even more user-friendly and precise.

One area of potential growth is in the integration of smart technology. Future models could feature more advanced digital controls and monitoring systems, allowing for greater precision and ease of use. These advancements will likely make methanol rotary evaporators even more indispensable in the laboratories of the future.

ZZKD Machinery and Instrument Equipment Co.,Ltd: Your Trusted Provider

ZZKD Machinery and Instrument Equipment Co.,Ltd is committed to providing high-quality distillation and extraction equipment, including top-of-the-line methanol rotary evaporators. Our products are designed with efficiency and reliability in mind, ensuring that our customers receive the best possible experience. With our extensive range of products, we are confident in meeting the diverse needs of laboratories across various industries.

Conclusion

Methanol rotary evaporators are pivotal in advancing laboratory processes, offering unparalleled efficiency and precision. For laboratories looking to enhance their capabilities, ZZKD Machinery and Instrument Equipment Co.,Ltd provides a range of high-quality methanol rotary evaporators. We invite you to visit our website to explore our products and discover how we can help meet your laboratory needs. Whether for academic research, pharmaceutical development, or any other scientific endeavor, our equipment is designed to deliver excellence and reliability.