In today’s rapidly evolving industrial landscape, sustainability has become more than just a buzzword; it’s a driving force behind innovation and efficiency. Ethanol recycling equipment, particularly solvent recovery machines, has emerged as a pivotal technology in this pursuit. In this article, we will delve deep into the world of solvent recycler machine, exploring its significance, applications, and benefits.

Understanding Ethanol Recycling Equipment

Ethanol recycling equipment, often referred to as solvent recovery machines, is a vital component of various industrial processes, especially in fields such as chemistry, pharmaceuticals, and bioengineering. These machines are designed to recover and reuse ethanol and other solvents, contributing to both cost savings and environmental conservation.

The Working Principle

Solvent recovery machines operate on a straightforward principle. They collect the used solvent, in this case, ethanol, from various processes. Then, through a series of distillation and purification steps, they separate the ethanol from contaminants and impurities, rendering it suitable for reuse. This closed-loop system not only minimizes waste but also reduces the need for purchasing new solvents, ultimately lowering operational costs.

Applications Across Industries

Solvent recycler machine finds application across a wide spectrum of industries:

1. Chemical Industry: In chemical manufacturing, where solvents are frequently used, solvent recovery machines play a crucial role in maintaining process efficiency while reducing waste.

2. Pharmaceuticals: Pharmaceutical companies rely on stringent quality standards. Ethanol recycling ensures that high-purity solvents are available for drug formulation, ensuring product quality and safety.

3. Bioengineering: In the biotech sector, where precision and purity are paramount, solvent recovery machines ensure that the solvents used in processes like cell culture and fermentation meet the required standards.

4. Research and Development: Laboratories and research facilities benefit from ethanol recycling equipment by optimizing solvent usage and minimizing environmental impact.

Advantages of Ethanol Recycling Equipment

The adoption of ethanol recycling equipment, particularly solvent recovery machines, offers a plethora of advantages to industries and businesses. Here are some key benefits:

Cost Efficiency

One of the most significant advantages is cost savings. By recycling ethanol, companies can significantly reduce their expenditure on purchasing new solvents. This cost-efficient approach directly contributes to improving the bottom line.

Environmental Impact

Ethanol recycling is a sustainable practice that aligns with global environmental goals. Minimizing the disposal of solvents and reducing the production of new ones helps in conserving resources and reducing greenhouse gas emissions.

Regulatory Compliance

Many industries must adhere to strict environmental regulations. Ethanol recycling equipment ensures compliance by minimizing solvent waste and emissions, avoiding potential fines and penalties.

Enhanced Product Quality

In sectors like pharmaceuticals and bioengineering, product quality is non-negotiable. Recycled ethanol is often of high purity, ensuring that end products meet stringent quality standards.

Choosing the Right Ethanol Recycling Equipment

Selecting the appropriate solvent recovery machine is crucial for optimizing its benefits. Consider the following factors:

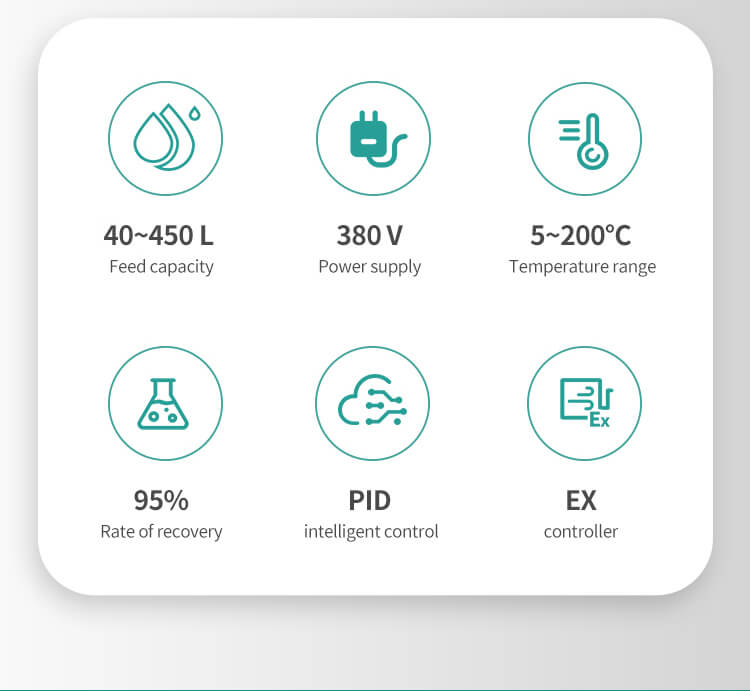

Capacity and Throughput of Ethanol Recycling Equipment

Choose equipment that aligns with your production capacity. Ensure it can handle the volume of solvent recycling required for your processes.

Quality and Purity Standards

Different industries have varying purity requirements. Ensure that the equipment you choose can meet the specific quality standards of your sector.

Energy Efficiency

Look for equipment that incorporates energy-efficient features to minimize operational costs and reduce environmental impact.

Ethanol recycling equipment, with a focus on solvent recovery machines, is a game-changer in today’s industrial landscape. Its ability to enhance sustainability, reduce costs, and improve product quality makes it a valuable asset for a wide range of industries. By adopting these technologies, businesses not only contribute to a greener future but also gain a competitive edge in an increasingly environmentally conscious world. Embrace solvent recycler machine, and take a significant step towards a more sustainable and efficient industrial future.