In the realm of chemical and biological pharmaceutical equipment, the high pressure hydrogenation reactors stands as a remarkable innovation. At ZZKD Machinery and Instrument Equipment Co., Ltd., where precision and excellence converge, these reactors are not just a product but a testament to over a decade of commitment to quality and innovation. In this article, we delve into the world of high pressure autoclave reactor, exploring their significance, working principles, applications, and the role ZZKD plays in shaping this industry.

I. Understanding High Pressure Hydrogenation Reactors

High pressure hydrogenation reactors are sophisticated pieces of equipment designed for a crucial process in chemical and pharmaceutical industries. They facilitate the addition of hydrogen gas to chemical compounds under elevated pressures and temperatures, leading to chemical transformations. These reactors are engineered to handle the rigors of high pressure chemistry with precision, ensuring safety and efficiency.

II. The Science Behind Hydrogenation

Hydrogenation is a chemical reaction that involves the addition of hydrogen atoms to unsaturated compounds. This process can have profound effects on the properties of molecules, making it a cornerstone in various industries. High pressure hydrogenation reactor provide the ideal environment for this reaction to occur with precision, enabling the creation of valuable products.

III. Applications of High Pressure Hydrogenation Reactors

1. Pharmaceutical Industry: High pressure hydrogenation reactors play a pivotal role in pharmaceutical manufacturing, enabling the synthesis of essential drugs and intermediates. These reactors ensure the purity and efficiency of drug production, meeting stringent quality standards.

2. Chemical Industry: In the chemical sector, high pressure hydrogenation reactors are used for diverse applications, including the production of specialty chemicals, polymers, and fine chemicals. The reactors’ ability to control reaction parameters makes them indispensable in achieving desired product outcomes.

3. Petrochemical Industry: Petrochemical processes often involve hydrogenation reactions to refine and upgrade hydrocarbon feedstocks. High pressure hydrogenation reactor facilitate these processes, contributing to the production of cleaner fuels and chemicals.

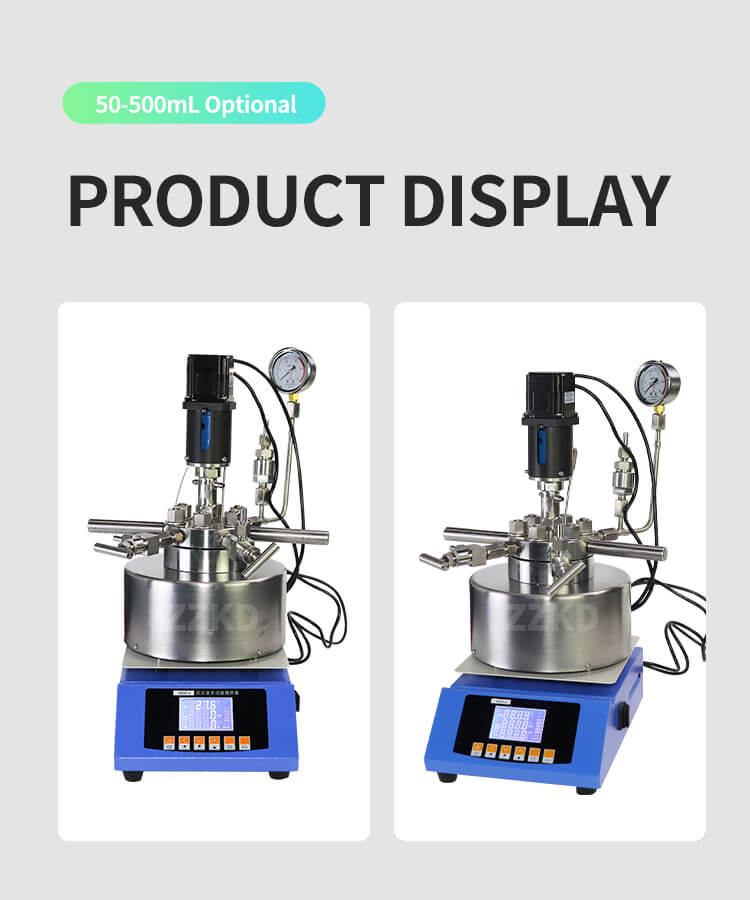

IV. ZZKD’s High Pressure Hydrogenation Reactors

1. Innovative Design: ZZKD’s high pressure hydrogenation reactors boast cutting edge design features that ensure optimal performance. These reactors are engineered for safety, efficiency, and ease of use, reflecting ZZKD’s dedication to excellence.

2. Customization: Recognizing that every application has unique requirements, ZZKD offers tailor made solutions. Their experienced OEM service caters to customer specifications, ensuring that the reactor precisely matches the intended use.

3. Worldwide Reach: ZZKD’s global presence, with warehouses in the United States, Spain, and Thailand, allows for efficient delivery and support to customers worldwide. Their commitment to dedicated customer service and technical support sets them apart in the industry.

V. Advancements in High Pressure Hydrogenation Technology

In recent years, high pressure hydrogenation technology has witnessed remarkable advancements. These include the integration of automation and control systems, enhancing the precision and reproducibility of reactions. Additionally, the development of novel catalysts has expanded the scope of hydrogenation reactions, making them more environmentally friendly and sustainable.

High pressure hydrogenation reactors are the backbone of chemical and pharmaceutical industries, enabling the creation of essential products that shape our world. At ZZKD, their commitment to quality, innovation, and customer satisfaction makes them a leading force in this field. As technology continues to advance, high pressure hydrogenation reactor will play an even more significant role in achieving chemical transformations safely and efficiently, driving progress in diverse industries.