A rotary evaporator is an essential piece of laboratory equipment used for efficient solvent removal, concentrating solutions, and performing other essential processes in chemical research and production. This article aims to provide a comprehensive guide on how to use a rotary evaporator effectively and safely. Whether you are a seasoned researcher or a novice in the field, this guide will help you understand the principles, setup, operation, and applications of a rotary evaporator.

I. Understanding the Basics

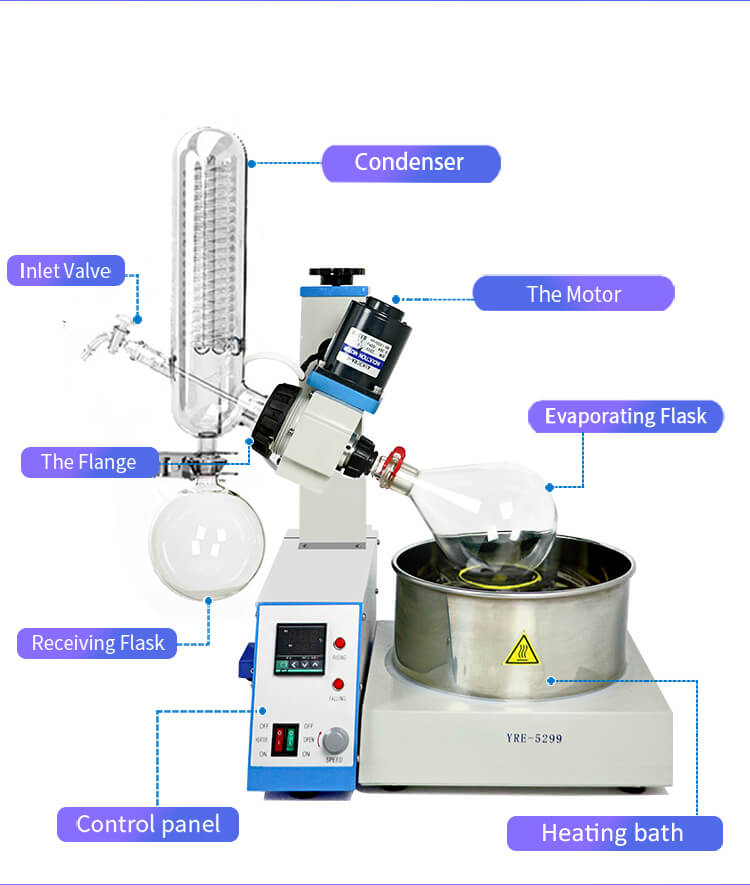

Before delving into the operational aspects, it is crucial to have a clear understanding of the basic components and principles of a rotary evaporator. This knowledge will help you make informed decisions during the setup and operation.

A. Rotary Evaporators Components

1. Flask: The flask, also known as the evaporation flask or boiling flask, holds the sample solution to be evaporated.

2. Condenser: The condenser cools the vapor produced by the solvent evaporation, causing it to condense back into a liquid form.

3. Rotating Flask and Motor: The rotating flask, also called the collection flask, is attached to the motor, which spins it to increase the evaporation surface area and facilitate efficient solvent removal.

4. Water Bath: The water bath provides a temperature-controlled environment to regulate the solvent’s boiling point and enhance the evaporation process.

B. Operational Principles

The rotary evaporator operates on the principle of reducing the pressure above the solvent, thereby lowering its boiling point. By rotating the flask and applying gentle heat, the solvent evaporates and rises into the condenser, where it cools and condenses. The condensed solvent is then collected in a separate flask, leaving behind the concentrated sample.

II. Setting Up the Rotary Evaporator

Proper setup is crucial for the safe and efficient operation of a rotary evaporator. Follow these steps to set up the equipment correctly:

A. Choose a Suitable Location

Select a well-ventilated area with sufficient space to accommodate the rotary evaporator and its accessories. Ensure that the power supply and water source are easily accessible.

B. Assemble the Apparatus

1. Attach the rotary evaporator to a stable support stand using clamps.

2. Connect the flask to the rotary evaporators by inserting it into the heating bath and securing it with the appropriate clamp.

3. Connect the condenser to the evaporator by inserting the glass tube into the receiving flask.

4. Fill the water bath with distilled water and connect it to the condenser.

III. Operating the Rotary Evaporator

Once the setup is complete, you can begin operating the rotary evaporator. Follow these steps for effective usage:

A. Preparing the Sample

1. Ensure that the sample solution is compatible with the rotary evaporator. Generally, samples with a density between 0.5% and 3% are suitable for this process.

2. Filter the sample solution to remove any particulate matter or impurities that may affect the evaporation process.

B. Setting Parameters

1. Set the desired rotation speed for the flask. The optimal speed depends on the sample size, viscosity, and desired evaporation rate. Start with a low speed and adjust as necessary.

2. Set the water bath temperature to control the boiling point of the solvent. Consult the solvent’s boiling point chart to determine the appropriate temperature.

C. Initiating the Evaporation Process

1. Start the rotation motor and gradually increase the speed until the desired rotation is achieved.

2. Switch on the water bath and set it to the desired temperature. Allow the system to stabilize for a few minutes.

3. Carefully add the sample solution to the flask, ensuring that it does not exceed the recommended volume.

D. Monitoring the Process

1. Regularly check the condenser for any blockages or buildup. Clean if necessary to maintain efficient cooling.

2. Monitor the collection flask and empty it periodically to prevent overflow.

IV. Application: Concentration of Natural Extracts

To illustrate the practical application of a rotary evaporator, let’s consider the concentration of natural extracts for pharmaceutical or food supplement production.

In this case, a rotary evaporator is used to remove the solvent from the natural extract while preserving the active compounds. By controlling the evaporation parameters, such as temperature and rotation speed, it is possible to achieve efficient concentration without degrading the extract.

The concentrated extract obtained from the rotary evaporator can then be further processed or analyzed for quality control purposes.

V. Safety Considerations

When using a rotary evaporator, it is crucial to prioritize safety. Here are some key safety considerations to keep in mind:

1. Always wear appropriate personal protective equipment (PPE), including lab coats, gloves, and safety goggles.

2. Handle the glassware with care to avoid breakage. In case of any damage, replace the glassware before proceeding.

3. Avoid working alone in the laboratory and ensure that someone is aware of your activities.

4. Use heat-resistant gloves or tongs when handling hot components.

5. Do not leave the rotary evaporator unattended during operation.

Using a rotary evaporator can greatly enhance the efficiency of solvent removal and concentration processes in various scientific applications. By understanding the fundamental principles, setting up the equipment correctly, and following safe operational practices, you can maximize the benefits of this versatile laboratory tool. Whether you are working in research, pharmaceuticals, or any other field that requires solvent evaporation, a rotary evaporator is an invaluable asset that can streamline your workflow and yield high-quality results.