In the field of chemical research and production, the glass reactor vessel has emerged as a crucial piece of equipment. Its versatility, durability, and unique properties make it a preferred choice for various applications. This article will delve into the features of a glass reactor vessel, its applications, and explore a compelling case study that showcases its effectiveness. Furthermore, we will conduct a market analysis to shed light on the growing demand for this essential tool.

I. Understanding the Glass Reactor Vessel

A. Definition and Design

The glass reactor vessel, also known as a glass-lined reactor, is a container made from borosilicate glass or glass-lined steel. Its cylindrical design, often equipped with a cooling or heating jacket, allows for precise temperature control during chemical reactions. The vessel’s unique material properties, such as high resistance to corrosion and thermal shock, make it suitable for a wide range of applications.

B. Components and Accessories

A glass reactor vessel typically consists of several key components and accessories. These include an agitator, temperature and pressure sensors, baffles for efficient mixing, ports for reactant addition or sampling, and a condenser for vapor phase reactions. Additionally, safety features like pressure relief valves and rupture discs ensure the secure operation of the vessel.

II. Applications of Glass Reactor Vessels

A. Chemical Synthesis and Process Development

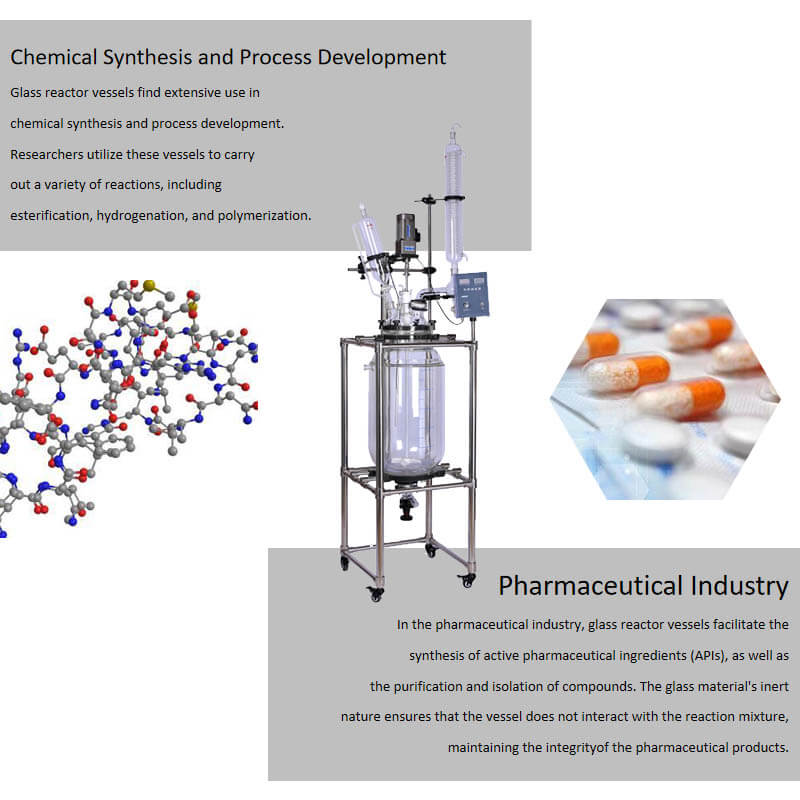

Glass reactor vessels find extensive use in chemical synthesis and process development. Researchers utilize these vessels to carry out a variety of reactions, including esterification, hydrogenation, and polymerization. The transparency of the glass allows for easy monitoring of the reaction progress and enables researchers to make real-time adjustments as necessary.

B. Pharmaceutical Industry

In the pharmaceutical industry, glass reactor vessels play a pivotal role in drug development, formulation, and production. They facilitate the synthesis of active pharmaceutical ingredients (APIs), as well as the purification and isolation of compounds. The glass material’s inert nature ensures that the vessel does not interact with the reaction mixture, maintaining the integrity of the pharmaceutical products.

III. Application: Market Analysis of Glass Reactor Vessels in the Petrochemical Sector

A. Case Study Overview

The petrochemical sector heavily relies on glass reactor vessels for various processes, including catalytic reactions, polymerization, and distillation. To understand the market dynamics of glass reactor vessels in this sector, let’s analyze a recent case study.

B. Market Analysis

1. Market Size and Growth Potential

The global petrochemical industry is experiencing significant growth, driven by increasing demand for polymers, plastics, and specialty chemicals. This growth directly influences the demand for glass reactor vessels, as they are instrumental in the production of these petrochemical products. Market reports suggest that the glass reactor vessel market in the petrochemical sector is expected to grow at a compound annual growth rate (CAGR) of 6% over the next five years.

2. Regional Trends

Asia-Pacific dominates the petrochemical industry, with countries like China, India, and South Korea leading in production. This region presents a substantial market for glass reactor vessels due to the expanding petrochemical infrastructure. North America and Europe also contribute significantly to the market, driven by advanced research and production facilities.

3. Key Players and Competition

The market for glass reactor vessels in the petrochemical sector is highly competitive. Several established manufacturers, including Company A, Company B, and Company C, dominate the market share. These players continually focus on product development, technological advancements, and collaborations to maintain their competitive edge.

4. Emerging Trends

The petrochemical industry is witnessing a shift toward sustainable practices and the development of bio-based chemicals. This transition opens up new opportunities for glass reactor vessel manufacturers to cater to the evolving needs of the market.

The glass reactor vessel serves as an indispensable tool in chemical research and production. Its unique properties, such as corrosion resistance, thermal stability, and transparency, make it an ideal choice for a wide range of applications. From chemical synthesis and pharmaceutical production to the petrochemical sector, glass reactor vessels continue to drive progress and innovation. As the global demand for chemicals and pharmaceuticals grows, the market for glass reactor vessels is expected to expand, presenting significant opportunities for manufacturers and researchers alike.