Glass reactor system introduction

A glass reactor system is a piece of laboratory equipment used for chemical synthesis, purification, and process development. It typically consists of a reaction vessel made of borosilicate glass, which is resistant to thermal shock and chemical corrosion. The glass reactor is often enclosed in a jacket that allows for temperature control during the reaction.

The glass reactor system also includes other components such as a stirring mechanism, a heating and cooling system, a vacuum or pressure system, and various ports for adding or removing materials, gases, or liquids.

Glass reactor systems are widely used in chemical, pharmaceutical, and biotech industries for various applications such as chemical synthesis, crystallization, distillation, and reflux. They are particularly useful for reactions that require precise temperature and pressure control and for reactions that generate toxic or hazardous products.

A glass reactor system provides a safe and efficient way to perform chemical reactions on a laboratory scale.

Glass reactor system Features:

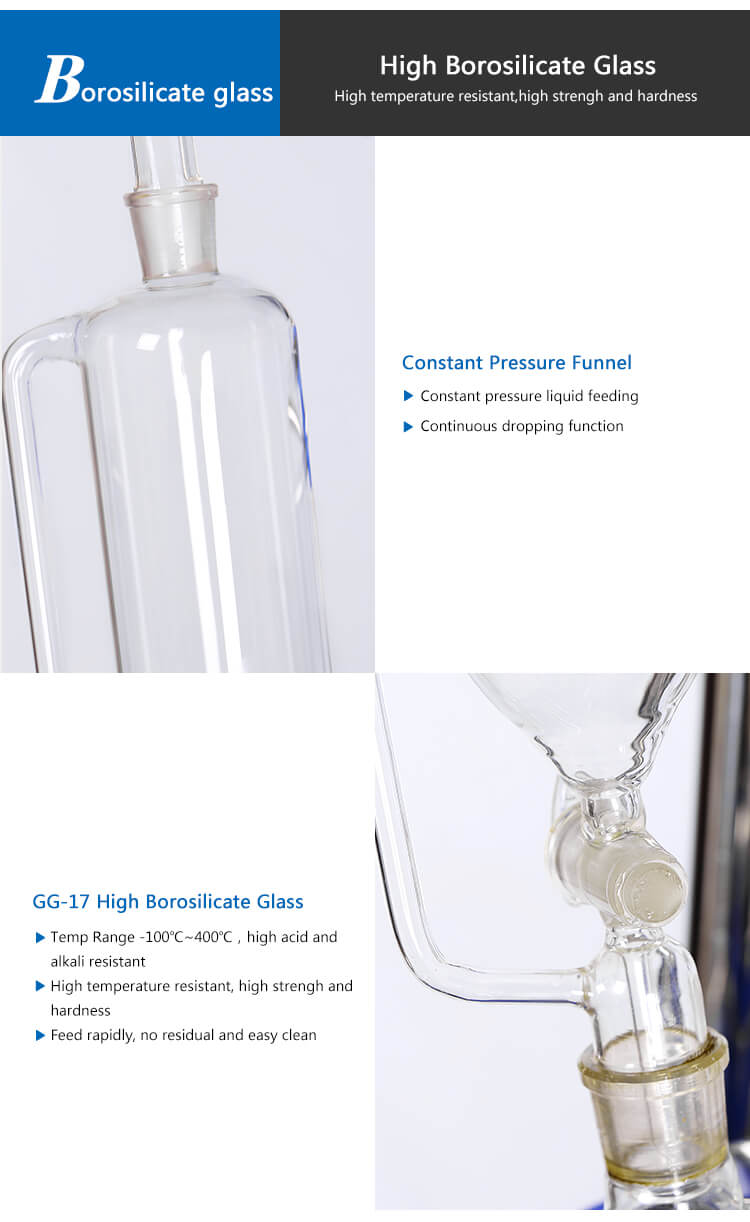

Borosilicate glass construction: Glass reactors are typically made of borosilicate glass, which is highly resistant to thermal shock and chemical corrosion, making it suitable for a wide range of chemical reactions.

Temperature control: Most glass reactor systems have a jacket that surrounds the reaction vessel and can be filled with a heating or cooling fluid to control the temperature of the reaction.

Stirring mechanism: A glass reactor system typically has a motorized stirring mechanism, which allows for efficient mixing of the reaction components.

Vacuum or pressure control: Glass reactor systems can be used under vacuum or pressure to facilitate specific reactions or purification processes.

Ports and accessories: Glass reactor systems often have various ports and accessories, such as inlet and outlet ports for adding or removing materials, sampling ports for monitoring the reaction, and condensers for distillation or reflux.

Safety features: Glass reactor systems may include safety features such as pressure relief valves, temperature sensors, and alarms to prevent accidents or damage to the equipment.

Scalability: Glass reactor systems can be designed to accommodate a range of reaction volumes, from a few milliliters to several liters, making them suitable for both laboratory-scale and pilot-scale experiments.

Glass reactor system Application:

Chemical synthesis: Glass reactors are used to perform chemical reactions such as esterification, hydrogenation, oxidation, and polymerization.

Crystallization: Glass reactors are used to grow and purify crystals, which can be used for drug development, material science, and other applications.

Distillation: Glass reactors can be used for distillation processes such as fractional distillation, steam distillation, and vacuum distillation.

Reflux: Glass reactors are used for reflux reactions, which involve boiling a reaction mixture and condensing the vapors back into the reaction vessel.

Purification: Glass reactors can be used for purification processes such as chromatography and recrystallization.

Hydrogenation: Glass reactors are commonly used in hydrogenation reactions, which involve the addition of hydrogen to unsaturated organic compounds.

Photocatalysis: Glass reactors can be used for photocatalytic reactions, which involve the use of light to drive chemical reactions.

Supporting Equipment for Glass reactor system:

DLSB-100/30 Refrigerated Circulator

Storage Volume: 100L

Low temperature range: -30℃~RT

Refrigeration capacity: 468~13025W

Rated Power: 4135W

SHZ-C Water Circulating Vacuum Pump

Power: 370W

Flow(L/min): 80

Lift(m): 12

Max.Vacuum(Mpa): 0.098

Tank Capacity: 50L

Case : ZZKD Company Selling Glass reactor system to a Portuguese Customer

ZZKD is a leading manufacturer and supplier of glass reactor systems to customers worldwide. Recently, the company sold a glass reactor system to a customer in Portugal. The customer is a research institution that specializes in pharmaceuticals and drug development.

The customer needed a glass reactor system that could accommodate various types of chemical reactions and be operated under controlled conditions. They required a system with precise temperature control, efficient stirring, and a range of accessories for adding and removing materials.

ZZKD provided the customer with a glass reactor system that met all their requirements. The system was made of high-quality borosilicate glass, had a jacket for temperature control, and a motorized stirring mechanism for efficient mixing. It also had various ports and accessories for adding and removing materials and a vacuum system for pressure control.

The customer was highly satisfied with the glass reactor system provided by ZZKD. They found it to be reliable, easy to use, and efficient in performing various chemical reactions. They also appreciated the prompt customer service and technical support provided by ZZKD during the installation and operation of the system.

In conclusion, ZZKD’s glass reactor system proved to be a reliable and efficient solution for the Portuguese customer’s needs, and the customer provided positive feedback about the product and the company’s services.