The rotary evaporator, also known as a rotovap, is a laboratory instrument used for efficient and gentle evaporation of solvents from samples. Various scientific fields, including chemistry, pharmaceuticals, food and beverage, widely use it. This article aims to provide a comprehensive understanding of the rotary evaporator’s working principle, its components, and its applications.

Working Principle of a Rotary Evaporator

The rotary evaporator utilizes the principle of evaporation to separate solvents from samples. It consists of three main components: a heat source, a vacuum system, and a rotating flask with a sample.

The process starts by placing the sample in a rotating flask, partially immersing it in a heated water bath or oil bath. Then, the flask rotates, increasing the surface area exposed to the heat source, facilitating evaporation. To accelerate the process, researchers apply a vacuum to lower the boiling point of the solvent.

As the solvent evaporates, it travels through a condenser, where it is cooled and converted back into a liquid. The condensed solvent collects in a separate flask, while the remaining sample residue stays in the rotating flask. By controlling the temperature, vacuum pressure, and rotation speed, precise and efficient separation of solvents can be achieved.

The Selling Points of Rotary Evaporators

Rotary evaporators, also known as rotovaps, are highly versatile laboratory instruments that offer several compelling selling points for researchers, scientists, and professionals in various industries.

1. Efficient Solvent Evaporation: Rotary evaporators provide efficient and rapid evaporation of solvents from samples. By combining gentle heating with vacuum pressure, these instruments accelerate solvent evaporation, significantly reducing processing time. The increased surface area achieved through the rotation of the flask enhances evaporation rates, allowing for quicker sample preparation and analysis.

2. Precise Temperature Control: Temperature control is crucial in evaporation processes to preserve the integrity of the samples and prevent degradation of volatile compounds. Rotary evaporators feature precise temperature control systems that enable users to maintain optimal temperature conditions throughout the evaporation process. This level of control ensures reproducibility and accuracy in experiments and helps to protect sensitive samples.

3. Versatility in Sample Types: Rotary evaporators can handle a wide range of sample types, making them suitable for diverse applications. Whether it is liquid solutions, suspensions, or solid samples dissolved in solvents, rotary evaporators can effectively evaporate the solvent and recover the desired compounds. This versatility allows researchers to work with various sample types without the need for multiple specialized instruments.

4. Solvent Recovery and Sustainability: Rotary evaporators contribute to sustainable laboratory practices by enabling efficient solvent recovery. Rotary evaporators condense and collect evaporated solvents for reuse, reducing solvent consumption, and minimizing waste generation. This feature not only reduces operational costs but also promotes environmental responsibility and sustainable research practices.

Application of Rotary Evaporators in the Pharmaceutical Industry

The pharmaceutical industry relies on advanced technologies and equipment to ensure the development, production, and quality control of drugs and therapies. Rotary evaporators have emerged as indispensable tools within the pharmaceutical sector, offering numerous applications that contribute to the efficiency and success of pharmaceutical research, development, and manufacturing processes. Here are some key applications of rotary evaporators in the pharmaceutical industry:

1. Solvent Recovery and Recycling: Solvents play a vital role in pharmaceutical synthesis, formulation, and extraction processes. Pharmaceutical companies widely use rotary evaporators for efficient solvent recovery, reclaiming valuable solvents, and reducing production costs. By applying vacuum and controlled heating, rotary evaporators enable the separation of solvents from drug samples, leaving behind the desired compounds for further processing. Users can reuse the recovered solvents, minimizing waste, and promoting sustainability.

2. Concentration of Solutions: Pharmaceutical research often involves working with dilute solutions that need to be concentrated for analysis, formulation, or stability testing. Rotary evaporators provide a quick and efficient method for concentrating solutions by evaporating the excess solvent. Rotary evaporators enable precise concentration by controlling temperature, vacuum pressure, and rotation speed, achieving desired concentration levels without compromising pharmaceutical compound integrity.

3. Purification of Active Pharmaceutical Ingredients (APIs): The purification of APIs is a critical step in drug development and manufacturing. Rotary evaporators facilitate the separation and purification of APIs from complex mixtures. By evaporating unwanted solvents and impurities, rotary evaporators help in obtaining highly pure and concentrated pharmaceutical compounds. This purification process ensures the integrity, safety, and efficacy of the final drug product.

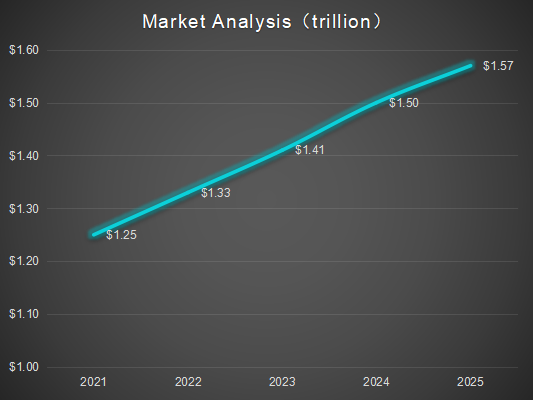

Market Analysis: Pharmaceutical Industry

The pharmaceutical industry is witnessing substantial growth globally, driven by factors such as increasing population, rising healthcare expenditure, and advancements in drug development. The demand for rotary evaporators within the pharmaceutical sector is expected to expand significantly. Here are a few key market insights:

1. Market Size: The global pharmaceutical industry was valued at over $1.25 trillionin 2020 and is projected to reach $1.57 trillion by 2025, with a compound annual growth rate (CAGR) of 4.6% during the forecast period.

2. Increasing Research and Development: The pharmaceutical industry heavily relies on research and development activities to introduce new drugs and therapies. Rotary evaporators are crucial in drug development, facilitating solvent recovery, concentration, and purification, supporting R&D endeavors.

3. Stringent Regulatory Standards: The pharmaceutical industry is subject to strict quality control regulations to ensure the safety and efficacy of drugs. Rotary evaporators ensure regulatory compliance by achieving required purity and concentration levels, indispensable in pharmaceutical manufacturing.

4. Growing Demand for Generic Drugs: The rising demand for cost-effective healthcare solutions and the expiration of patents for several branded drugs have fueled the market for generic drugs. Rotary evaporators help pharmaceutical manufacturers optimize production processes, reduce costs, and improve the efficiency of generic drug production.

5. Emerging Markets: Developing regions, such as Asia Pacific and Latin America, are witnessing significant growth in their pharmaceutical sectors. Emerging markets provide profitable prospects for rotary evaporator manufacturers as pharmaceutical firms expand and invest in advanced equipment.

Conclusion

Rotary evaporators play a crucial role in various scientific fields, with the pharmaceutical industry being a prominent user. Their ability to facilitate solvent recovery, concentration, and purification makes them invaluable tools for drug development and production. As the pharmaceutical industry continues to grow and evolve, the demand for rotary evaporators is expected to rise, driven by increasing R&D activities, regulatory compliance requirements, and the pursuit of cost-effective drug manufacturing processes. Manufacturers and suppliers of rotary evaporators should focus on innovation, product enhancements, and market expansion strategies to tap into the growing opportunities presented by the pharmaceutical sector.